For the configuration of 500-600 thp (tons/hour) stone crushing equipment with cone crusher, the following is a detailed answer:

Overview of 500-600 thp (tons/hour) stone crushing equipment

Stone crushing plant is mainly used to crush large pieces of stone into required particle sizes, and is widely used in construction, roads, railways, water conservancy and other fields. Within the production capacity range of 500-600 thp, the configuration of cone crusher can ensure efficient and stable crushing effect.

Configuration of 500-600 thp (tons/hour) stone crushing equipment

1. Type: multi-cylinder hydraulic cone crusher (such as HPC500)

2. Production capacity: According to the cavity type selection of cone crusher, the processing capacity can reach 365-790t/h, which meets the production needs of 500-600 thp.

3. Crushing cavity type: a variety of cavity types are available to adapt to crushing operations with different particle size requirements.

4. Motor power: usually equipped with a motor of about 400kw, providing powerful crushing power.

5. Structural features: Made of high manganese steel, wear-resistant and corrosion-resistant; with hydraulic adjustment of discharge port, overload protection and other functions.

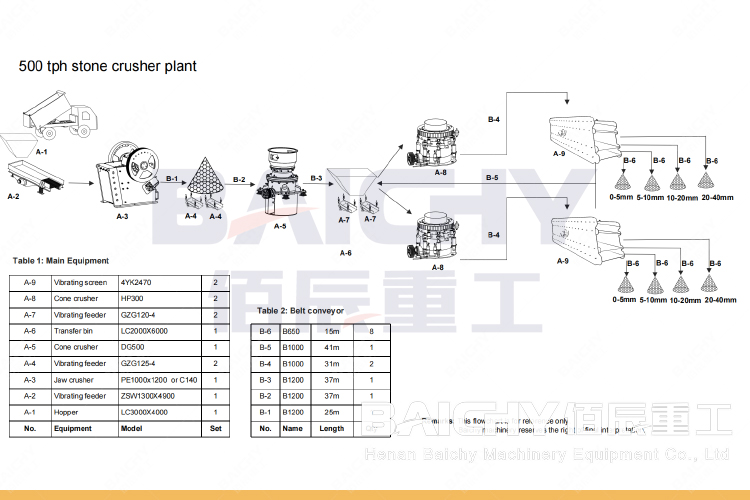

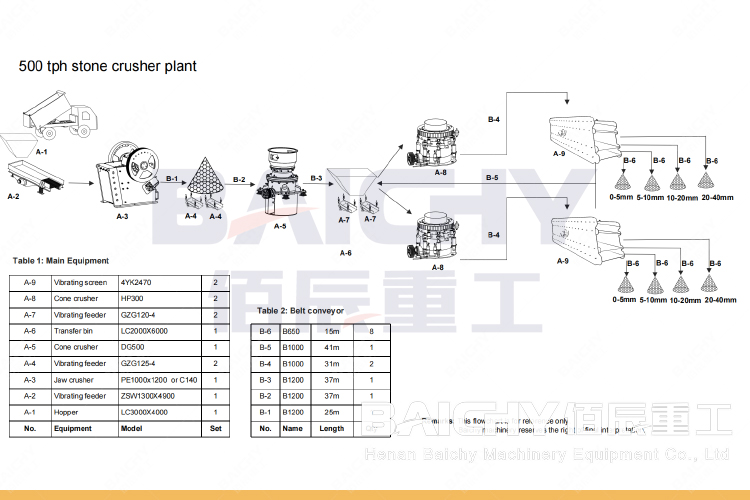

500-600 thp (tons/hour) stone crushing equipment auxiliary equipment

1. Vibrating feeder: used to feed the stone to be crushed into the cone crusher evenly and continuously.

2. Jaw crusher (optional): as a primary crushing equipment, it performs preliminary crushing of large pieces of stone to reduce the particle size and facilitate the subsequent processing of the cone crusher.

3. Vibrating screen: used to screen the crushed stone and separate the particle size products that meet the requirements.

4. Belt conveyor: used to transport the crushed stone from the cone crusher to the vibrating screen or other equipment.

Working principle of 500-600 thp (tons/hour) stone crushing equipment

The working principle of cone crusher is to drive the horizontal shaft to rotate through the motor, and the horizontal shaft drives the eccentric sleeve to rotate through the gear transmission. The eccentric sleeve drives the main shaft to make the moving cone part swing, thereby generating periodic relative motion between the eccentrically swinging moving cone liner and the fixed cone liner. The material to be crushed enters the crusher from the upper feed port, is squeezed and bent in the crushing chamber and crushed, and the crushed material is discharged from the discharge port at the bottom of the crusher.

Advantages of 500-600 thp (tons/hour) stone crushing equipment

1. High efficiency and stability: cone crusher adopts advanced crushing technology and structural design, with high efficiency and stable crushing performance.

2. Strong adaptability: a variety of chamber types are available to adapt to crushing operations with different particle size requirements; at the same time, different auxiliary equipment can be configured to form a complete crushing production line.

3. Energy saving and environmental protection: hydraulic adjustment of discharge port, overload protection and other functions are adopted to reduce energy consumption and failure rate; at the same time, noise and dust pollution are reduced, which meets environmental protection requirements.

4. Convenient maintenance: the equipment has a compact structure and simple operation; it is made of wear-resistant materials to reduce wear and maintenance costs.

The above is an introduction to the configuration of 500-600 thp stone crushing equipment with cone crusher. The specific configuration can be adjusted and optimized according to actual production needs.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.