|

Equipment configuration

|

Hopper, ZSW1100x4900 vibrating feeder, PE900x1200 jaw crusher, HPC400/CS220 cone crusher(PF1320 impact crusher), Vibrating screen, Belt conveyor. |

|

Raw materials

|

This stone plant can crush more than 120 kinds of ore materials such as limestone, granite, basalt, Riverstone, and rocks. |

|

Feed Size

|

Less than 750mm |

|

Capacity

|

200-300www.baichychina.com/Crushing/C-series_jaw_crusher.htmlt/h |

|

Finished product

|

60 mm and down |

|

Design requirements

|

1.The required production capacity 2.The type, hardness, and abrasiveness grade of the crushed material 3.the maximum size of the feed 4.The size of the desired final fraction |

|

Advantages

|

Baichy Machinery designs and manufactures crushing and screening equipment with different configurations and capacity values according to customers' needs and preferences. The capacity values of our crushing and screening plants vary between 50-1000 tph. The configuration and layout of our crushing and screening plants are defined according to different standards. |

As a widely used screening equipment, the drum screen plays an important role in many fields due to its high efficiency, convenience, and environmental protection. The working principle is to control the sorting of materials based on the particle size.

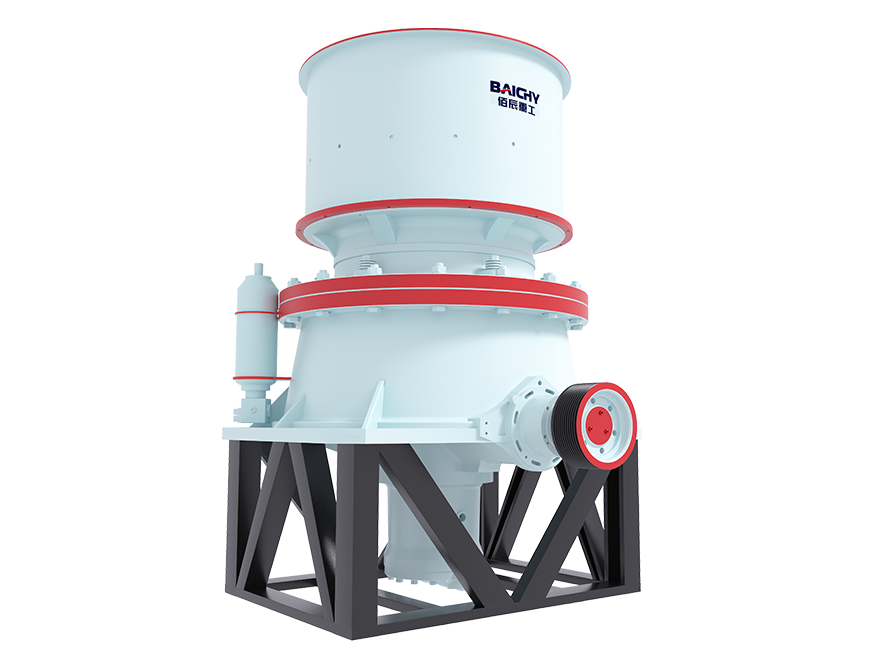

DG series single-cylinder hydraulic cone crusher is an advanced and efficient crushing equipment. Its unique single-cylinder hydraulic technology and superior performance characteristics play an important role in the medium and fine crushing of ores.

C110 jaw crusher: suitable for coarse crushing operations, capable of processing large pieces of raw materials and crushing them to a particle size suitable for further processing by the impact crusher.

PFW1230 impact crusher: As a secondary crushing equipment, it is suitable for medium and fine crushing operations, and can further crush the materials processed by the C110 jaw crusher to the required finished product particle size.

Under ideal working conditions, the combination of the C110 jaw crusher and PFW1230 impact crusher can meet the production demand of 200-300t/h. However, it should be noted that the actual output will be affected by factors such as material hardness, humidity, and particle size distribution.

When selecting equipment, the characteristics of raw materials and production requirements should be fully considered. For example, if the raw material contains a lot of soil or impurities, it may need to be pre-treated before crushing. In order to obtain the required finished product particle size, it is recommended to configure an appropriate screening system in the production line. This ensures uniformity and consistency in the finished product particle size.

The four-combination mobile station is widely used in various engineering projects due to its high flexibility, customizability, and efficiency. It can quickly adapt to different working environments and needs, provide efficient and accurate crushing and screening services, and provide strong support for the smooth progress of various engineering projects.

Impact crushers - high-quality impactors, Rock Crushing & Screening Plants, Crushing And Screening Plant, Stone Crusher For Sale

Cone Crushing - High Capacity And Superior Quality. Long Working Life Of Quick-Wear Parts. Stone Crusher Rock Crushing Plant for Sale.