Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

1. Modular, non-welded frame structure: The C100 jaw crusher adopts a modular, non-welded frame structure, with two hot-rolled steel side plates firmly bolted to the frame by precision-machined solid bolts. This design avoids the shortening of the equipment's durability due to stress concentration points (such as welding gaps) when the equipment is subjected to impact loads, thereby ensuring the equipment's fatigue resistance, reliability, and multiple installation methods.

2. High production and crushing ratio: The C100 jaw crusher is known for its powerful movable jaw movement and long eccentricity at the bottom of the crushing chamber. The eccentricity increases from top to bottom, thereby increasing the production and crushing ratio. This allows the C100 to maintain high production efficiency and crushing effect when handling a variety of materials.

3. Durable bearings: The C-series jaw crusher is equipped with an eccentric shaft bearing that is more durable than other crushers of the same grade. Its load-bearing capacity and labyrinth seal greatly extend the bearing life. This not only reduces maintenance costs but also ensures continuous and stable operation of the equipment.

| Model | C100 |

|---|---|

| Feeder Opening Size(mm) | 750x1060 |

| Max. Feeding Size(mm) | 600 |

| Outlet adjusting Range(mm) | 70-200 |

| Centrifugal Shaft Speed(rmp) | 260 |

| Motor Power(kw) | 132 |

| Capacity(t/h) | 150-300 |

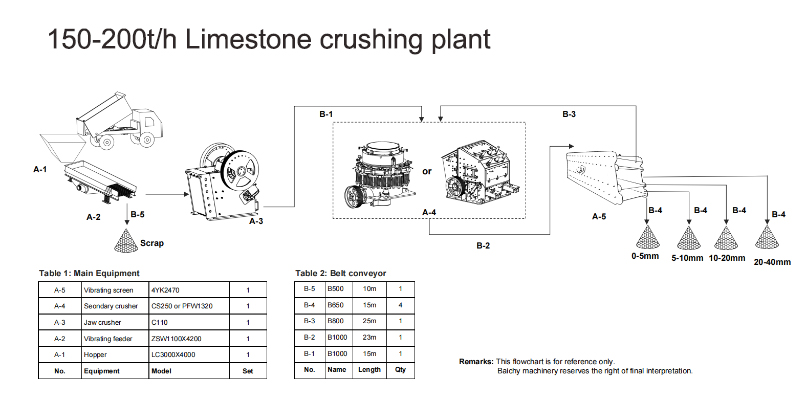

| Capacity | 150-200t/h |

|---|---|

| Feeder | ZSW1142 |

| Jaw Crusher | C100 |

| Impact Crusher | PFW1315 |

| Vibrating Screen | 4YK2160 |

| Belt | 7 Sets |

• The raw materials are first crushed by a C100 jaw crusher, and the crushed materials are conveyed to the PFW1315 impact crusher by conveyor for further crushing until the required particle size is reached.

• The crushed materials are conveyed to the 4YK2160 vibrating screen by conveyor for screening, and materials of different specifications are screened out to meet the needs of different customers.

• The whole production line is reasonably configured, and the connection between equipment is smooth, which can achieve efficient and stable crushing production.

• The selection of equipment such as the C100 jaw crusher, PFW1315 impact crusher, and 4YK2160 vibrating screen ensures the stability and efficiency of the production line.

• The equipment has superior performance and large processing capacity, which can meet the production needs of 150-200t/h.

• The production line configuration is flexible and can be adjusted and optimized according to actual production needs.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!