Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

The steep slope cone design with large swing frequency and large inclination angle makes the processing capacity about 40% greater than that of ordinary cone crushers.

The feed inlet is also larger than that of ordinary cone crushers, so the production capacity of single-cylinder cone crushers is higher.

The lamination crushing principle is adopted, and the products after crushing are mostly cubic structures, which reduces needle-like materials, makes the particle size more uniform, and improves the production quality.

The unique crushing cavity shape and lamination crushing principle significantly increase the proportion of cubes in the finished product, reduce needle-like stones, and make the particle size more uniform.

A variety of crushing cavities are adopted, and the cavity shape required by the particle size can be adjusted at will.

By replacing the eccentric sleeve, the size of the eccentric distance can be changed to meet the needs of different crushing materials.

| Model | Cavities | Feeding Size(mm) | Adjusting Range of Discharge Opening (mm) | Capacity(t/h) | Power(kw) |

|---|---|---|---|---|---|

| DG300 | Coarse | 400 | 35-100 | 350-750 | 250-315 |

| Medium | 300 | 25-70 | 260-500 | ||

| Fine | 150 | 18-40 | 180-370 |

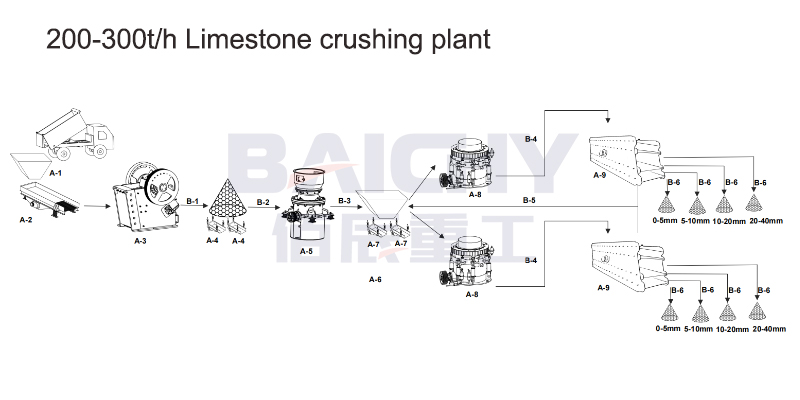

| NO. | Product Name | Model | Quantity |

|---|---|---|---|

| 1 | Hopper | - | 1 |

| 2 | Vibrating feeder | ZSW1349 | 1 |

| 3 | Jaw Crusher | PE1000X1200 | 1 |

| 4 | Cone Crusher | HP500 | 1 |

| 5 | DG Cone Crusher | DG-400 | 1 |

| 6 | Vibrating Screen | 4YK2470 | 1 |

| 7 | Belt | B1000 | - |

The production line is mainly equipped with a DG400 cone crusher with a designed production capacity of 200 tons/hour. The production line integrates key equipment such as crushing, screening, and conveying, aiming to achieve efficient, stable, and environmentally friendly crushing operations to meet the needs of stone crushing in various industrial applications.

1. Efficient production: The DG400 cone crusher has efficient crushing capacity, combined with optimized production processes, it can achieve stable production of 200t/h.

2. Uniform product size: Adopting the lamination crushing principle, the crushed product has uniform particle size and low needle-like content, meeting high-quality requirements.

3. Environmental protection and energy saving: Equipped with dust removal equipment to reduce dust pollution in the production process; at the same time, the production line design focuses on energy saving and consumption reduction to reduce production costs.

4. Intelligent control: The production line can be equipped with advanced control systems to achieve automatic control and remote operation, improving production efficiency and safety.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!