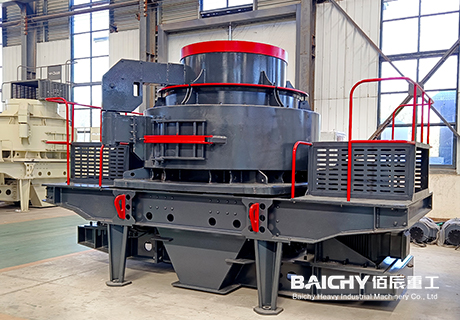

Compared with traditional sand-making machines, VSI sand-making machines can save up to 50% of energy. During the crushing process, the materials impact and crush each other, without direct contact with metal components, reducing corner pollution. At the same time, the ingenious self-circulation design of the airflow inside the vortex chamber effectively eliminates dust pollution.

Applicable materials: including river pebbles, granite, marble, limestone, quartz, iron ore, abrasives, refractory materials, cement clinker, concrete aggregates, etc.

The high-efficiency fine crusher adopts advanced crushing technology and design to achieve efficient material crushing. Compared with traditional fine crushers, its production efficiency is higher and it can significantly increase the overall production capacity of the production line. The materials crushed by the high-efficiency fine crusher have uniform particle size and high quality. It can effectively control the discharging particle size and ensure that the products meet the needs of high-standard construction. The finished sand is cubic in shape and has strong pressure resistance. More than 85% of the finished sand has a particle size of ≤5mm, which is suitable for high-standard construction needs.

High-efficiency fine crushers have a wide range of applications. It is suitable for fine and medium crushing of various hard and brittle materials, such as granite, basalt, cement clinker, quartz stone, emery, ore, iron ore, bauxite, river pebbles, etc.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!