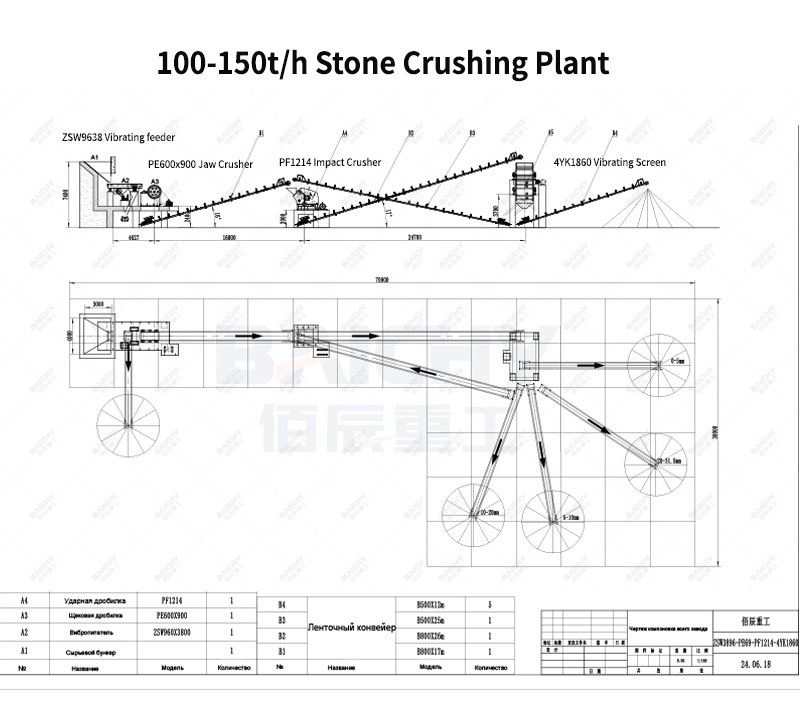

The process flow of compact fixed jaw crusher mainly includes material feeding, crushing, screening and discharging.

The material is evenly fed into the feed port of the crusher through feeding equipment (such as vibrating feeder or belt conveyor). The feed particle size must meet the equipment requirements to avoid blocking the feed port with too large materials. The feeding speed should be uniform to ensure the crushing efficiency.

After the material enters the crushing chamber, the fixed jaw plate and the movable jaw plate squeeze, shear and impact the material to crush it. The movable jaw plate moves periodically through the eccentric shaft to achieve continuous crushing

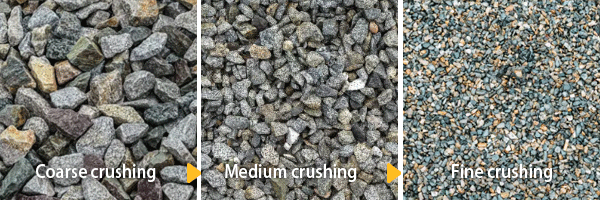

The crushed material can be screened by a vibrating screen or grading equipment. The material that meets the particle size requirements enters the next process, and the material that does not meet the requirements returns to the crusher for re-crushing. The selection of screening equipment should be based on the material characteristics and production requirements.

The crushed material is discharged from the discharge port and transported to the next process or storage area through conveying equipment (such as belt conveyor).

The process flow of compact fixed jaw crusher is simple and efficient. Through reasonable feeding, crushing, screening and discharging steps, it can achieve rapid crushing and classification of materials. In actual production, it is necessary to optimize the process flow according to the material characteristics and production requirements to ensure efficient and stable operation of the equipment.