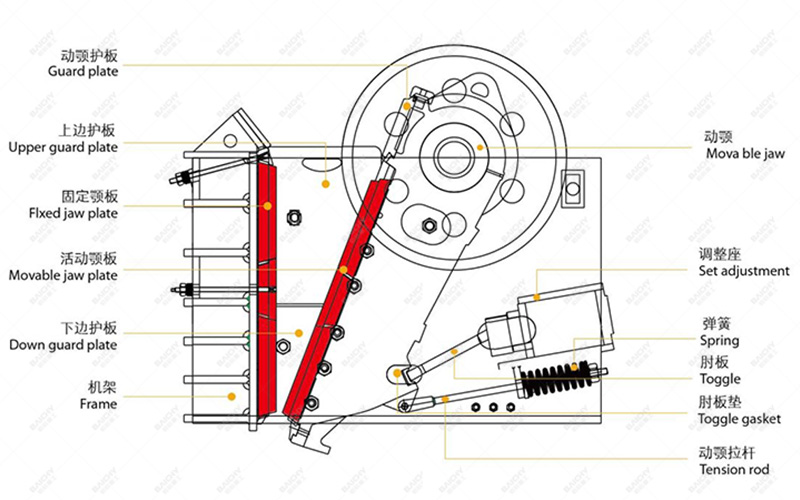

The working principle of the jaw crusher is mainly based on the relative movement of two jaw plates, one is a fixed jaw plate (fixed jaw), and the other is a movable jaw plate (movable jaw). The two form a crushing chamber that is larger at the top and smaller at the bottom. After the material is poured into the crushing chamber from the top entrance, it is crushed by the squeezing force between the movable jaw and the fixed jaw.

Specifically, the motor drives the belt and pulley to move the movable jaw up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw increases, thereby pushing the movable jaw plate closer to the fixed jaw plate, and the material is crushed multiple times through squeezing, rubbing, and grinding between the two jaw plates; when the movable jaw descends, the angle between the toggle plate and the movable jaw decreases, and the movable jaw plate leaves the fixed jaw plate under the action of the pull rod and spring. The crushed material is freely discharged through the discharge port at the bottom of the jaw cavity under the action of gravity. With the continuous rotation of the motor, the movable jaw performs periodic crushing and discharging to achieve batch production.