Fixed compact crusher application scenarios and configuration recommendations

1. Urban construction waste recycling

Recommended model: impact compact crusher

Configuration points: Install a magnetic separator to separate steel bars, set a soil removal screen at the discharge port, and produce 0-5mm/5-10mm/10-31.5mm recycled aggregate to meet the roadbed material standards.

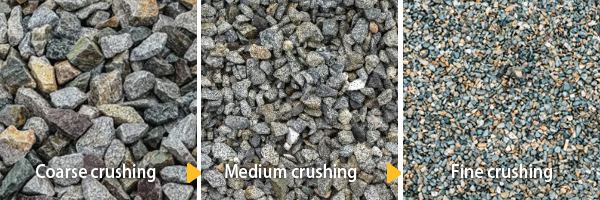

2. Granite sand production line

Recommended solution: jaw crusher + cone crusher compact combination

Data comparison: Compared with traditional production lines, the floor space is reduced by 40%, power consumption is reduced by 15%, and the needle-like content of the finished product is less than 8%.