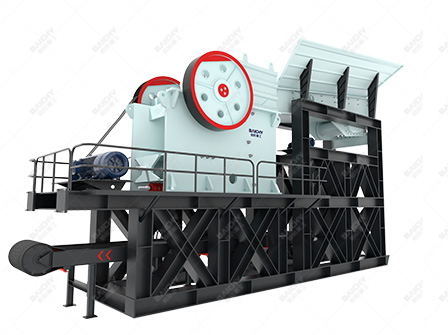

Stationary/Fixed crusher vs. mobile crusher

Stationary/Fixed: Suitable for long-term stable, high-volume projects, cost-effectiveness is prominent in large-scale production.

Mobile: Integrated vehicle chassis, can be quickly transferred, suitable for multi-site, short-term or dispersed operations, but the processing capacity and durability are usually lower than fixed.

Advantages and limitations of fixed crushers

Advantages:

High processing capacity: The single machine capacity can reach thousands of tons per hour, suitable for large-scale continuous operations.

Strong durability: Heavy-duty structural design, adaptable to harsh working conditions and long-term operation.

Controllable particle size: By adjusting the size of the discharge port, the specifications of the crushed product can be flexibly controlled.

Limitations:

High initial investment: supporting infrastructure (such as concrete foundation, power system) and conveying equipment are required, and the installation cost is high.

Low flexibility: Unable to move with the work surface, relying on trucks or conveying systems to transfer materials.

Complex maintenance: Large components require downtime for maintenance, and the maintenance cycle is long.