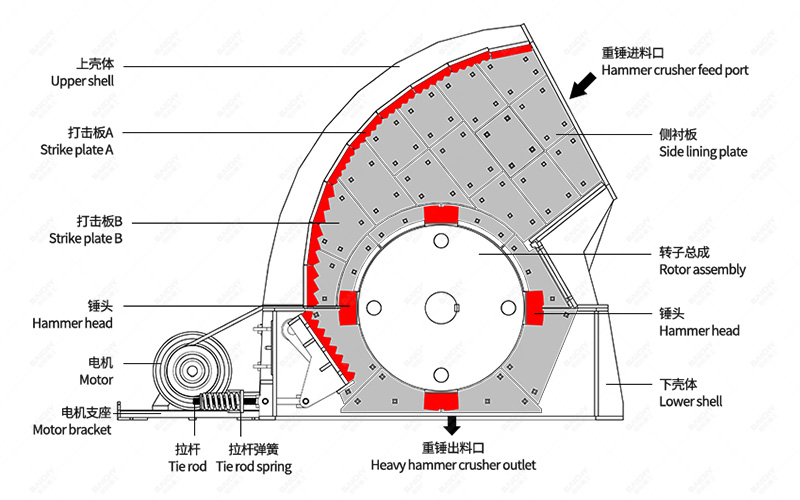

The working principle of limestone hammer crusher is mainly based on the high-speed rotating hammer head exerting impact force on the material to achieve the purpose of crushing. The following is a detailed description of the working principle:

1. Motor drive: The motor of the limestone hammer crusher drives the rotor to rotate at high speed through the V-belt and the large pulley. This is the power source of the entire crushing process.

Material feeding: The limestone material to be crushed is evenly fed into the crushing chamber of the crusher by the feeding equipment (such as a vibrating feeder or a belt feeder).

2. Primary crushing: When the material enters the crushing chamber, the high-speed rotating rotor drives the hammer head to hit the material for the first time. The impact force of the hammer head causes the material to break along its natural crack surface and weak tissue, thereby achieving the effect of primary crushing.

3. Multiple crushing: After the initial crushing, the material gains kinetic energy and hits the impact plate at high speed or collides with other materials, thereby achieving multiple crushing. In this process, the material gradually becomes smaller and moves toward the movable impact plate at the bottom of the crushing chamber.

4. Screening and discharging: When the particle size of the material is smaller than the gap between the hammer head and the movable impact plate, the material will be separated from the crushing chamber under the pressure of its own weight and other materials, and discharged from the lower hopper. At the same time, the crusher is usually equipped with a screen plate or sieve hole to further screen qualified materials.

5. Repeated crushing: If the particle size of the discharged material still does not meet the requirements, it can be sent to the crusher again for secondary or multiple crushing until it meets the production needs.