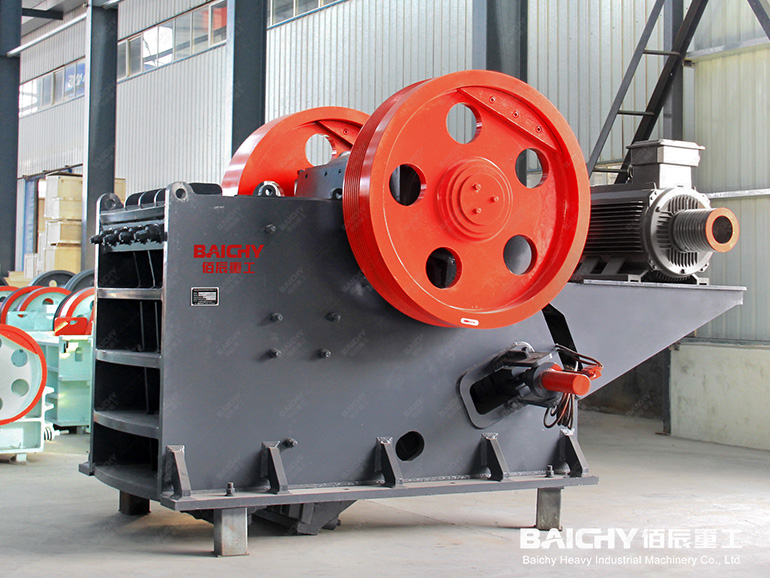

The working principle of the mining jaw crusher is to crush materials through the periodic reciprocating motion of the movable jaw. When the movable jaw approaches the fixed jaw, the material between the two jaw plates is crushed by crushing, splitting and bending and breaking; when the movable jaw leaves the fixed jaw, the material that has been crushed to a size smaller than the discharge port is discharged from the bottom by its own weight. This process is repeated until the material is crushed to the required particle size.

Mining jaw crushers are widely used in the mining industry, construction industry, road engineering, chemical industry and environmental protection field due to their high efficiency, energy saving and simple structure.