Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

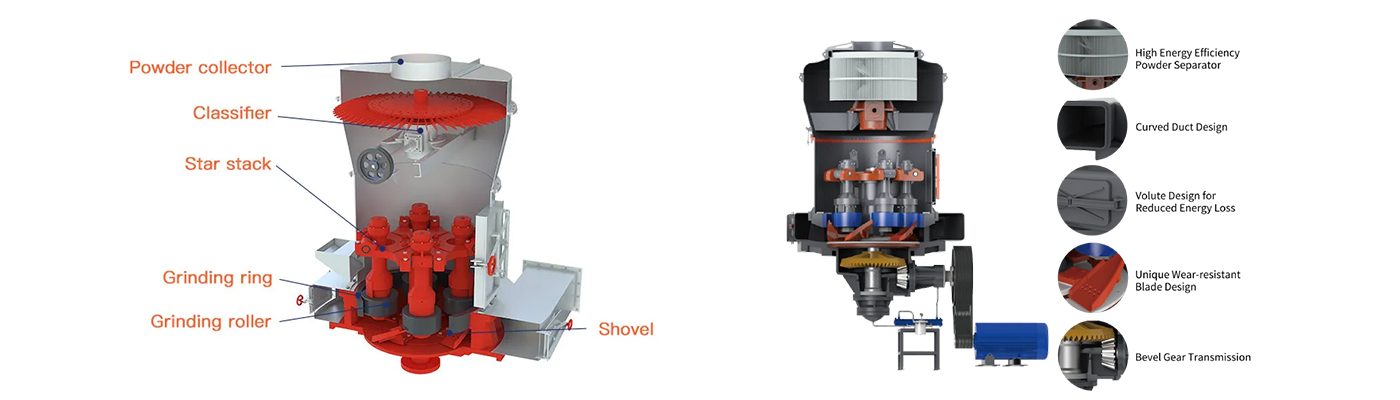

YGM Industrial Raymond Milll, also known as YGM Raymond mill or Raymond machine, is a high-efficiency grinding mill that replaces ball mills for processing mineral powder. It is a device used to grind solid raw materials into powder. Its working principle mainly relies on the internal grinding of the grinding head. The friction of the powder causes the material to be subjected to strong and shearing forces and is continuously refined during the grinding process, eventually reaching the required powder particle size.

Industrial Raymond mill has outstanding advantages such as strong systematicness, high screening rate, smooth transmission, high wear resistance, and easy maintenance.

1. Main machine improvement: increase the grinding roller, and grinding ring, increase the blade, increase the grinding surface and grinding force, and increase the output.

2. Improvement of the reducer: The reducer is changed to a new reducer. The main engine speed can be changed from a single speed to appropriately adjusted according to the user's needs. The grinding force can be increased to increase output.

3. Improvement of the classifier: The classifier adopts a built-in large-blade conical turbine classifier. The particle size of the finished product can be adjusted arbitrarily within 80-600 mesh, which improves the classification accuracy and airflow area.

4. Cyclone collector improvement: The cyclone collector is changed to a parallel four-cyclone collector, which improves the collection efficiency by more than 10%25 compared with a single cyclone collector.

5. Fan improvement: The fan is changed from an ordinary fan to a high-pressure fan. The wind pressure is doubled, which greatly improves the pneumatic transportation capacity.

Have Any Questions!