Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

• 900x1800 ball mill is suitable for grinding a variety of materials, such as ore, quartz sand, limestone, etc.

• Commonly used in the mineral processing industry, such as grinding gold ore, iron slag, steel slag, aluminum slag, etc.

• It can also be used for material grinding and powdering in building materials, chemical, and other industries.

The ball mill for gold mine is a device that uses round steel balls and gold ore to rotate together in the machine to crush and grind the ore into powder. Its main function is to grind and refine the gold ore to improve the flotation performance and gold extraction rate of the gold ore. This equipment is key equipment in the mining industry and directly affects the efficiency and product quality of gold mine production.

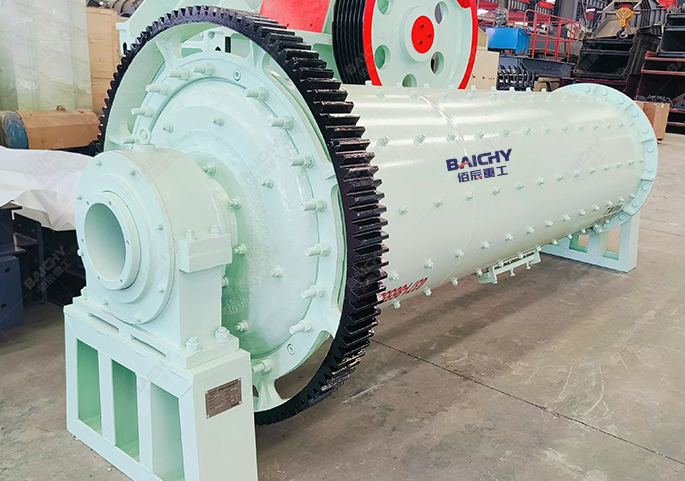

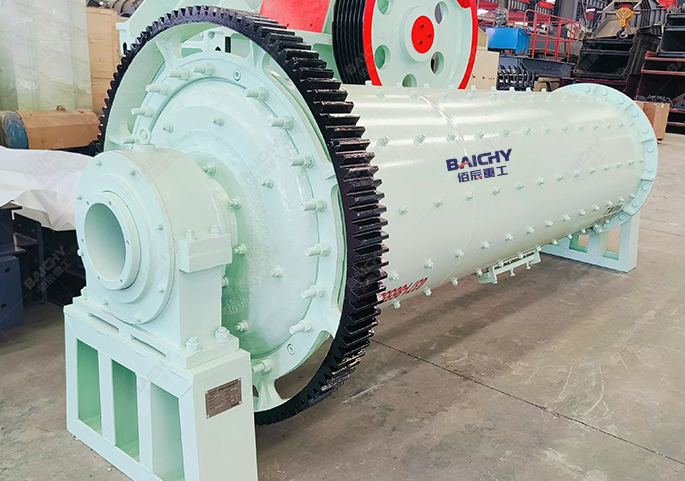

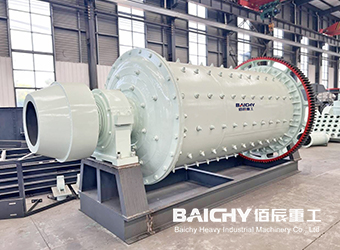

900x1800 Ball Mill

Gold Ore Ball Mill

Ball Mill for gold

Mining Ball Mill

| Model | Ф900×1800 |

|---|---|

| Cylinder Rotating Speed (r/min) | 36-38 |

| Ball weight(t) | 1.5 |

| Feeding Size(mm) | ≤20 |

| Discharging Size(mm) | 0.075-0.89 |

| Capacity(t/h) | 0.65-2 |

| Power(kw) | 18.5 |

Model: Ф900×1800, cylinder diameter: 900 mm, ball loading: 1.5 T, feed particle size: ≤20 mm, discharge particle size: adjustable between 0.03-0.89 mm, processing capacity: 1-3 T/H, cylinder speed: 36-38 r/min, motor power: 18.5 KW.

• It is mainly composed of the feeding part, discharging part, rotating part, transmission part (including reducer, small transmission gear, motor, electronic control), and other parts.

• The hollow shaft is made of cast steel, the inner lining is removable and has good wear resistance.

• The cylinder is inlaid with wear-resistant lining to increase service life.

• Process of gold ore dressing production line: The process of gold ore dressing production line includes multiple stages such as ore crushing, grinding, classification, cyanide leaching, activated carbon adsorption, etc. Among them, grinding is one of the key steps to extract concentrate and tailings.

• The role of the ball mill: A ball mill is a key piece of equipment for material grinding after material crushing. It is suitable for grinding various ores and other materials. In the gold ore dressing production line, the main function of the ball mill is to further grind the crushed ore to achieve a suitable particle size for subsequent ore dressing operations.

Have Any Questions!