Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

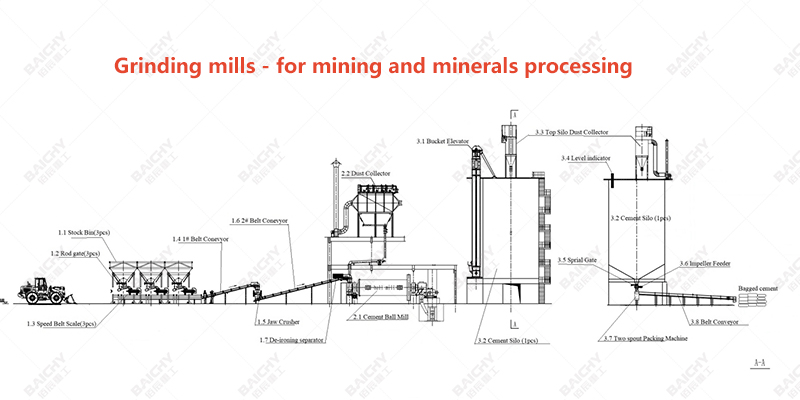

900x3000 ball mill is a medium-sized ball mill equipment, suitable for medium-scale production and processing, capable of processing various ores and other grindable materials. Through adjustment and control, it can achieve finer discharge particle size requirements to meet different process requirements.

1. When the mill rotates, the grinding body adheres to the lining plate on the inner wall of the mill body due to the inertial centrifugal force and rotates with the mill is brought to a certain height, and then falls like a projectile to crush the material in the cylinder.

2. There are also rolling and sliding phenomena between the grinding bodies, which mainly grind the materials.

3. The continuous addition of materials from the front bin rotates with the cylinder to form an extrusion of the materials. In addition, the height difference between the feed end and the discharge end and the forced ventilation in the mill make the materials move slowly from the feed end to the discharge end to complete the grinding operation.

Ball mill cylinder

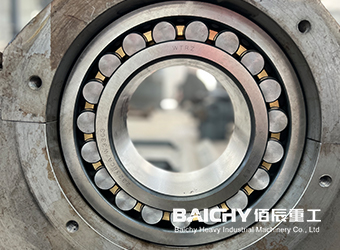

Ball mill bearing

Ball mill liner

Grinding media steel balls

| Model | Ф900x3000 |

|---|---|

| Cylinder Rotating Speed (r/min) | 36 |

| Ball weight(t) | 2.7 |

| Feeding Size(mm) | ≤20 |

| Discharging Size(mm) | 0.075-0.89 |

| Capacity(t/h) | 1.1-3.5 |

| Power(kw) | 22 |

The 900x3000 ball mill has become an indispensable and important piece of equipment in medium-scale production lines with its moderate specifications, moderate processing capacity, energy-saving design, flexible drive and feeding methods, wide application fields, reliable working principles, and clear technical parameters.

The output range of this model of ball mill is usually between 1.1-3.5t/h, which is suitable for the processing of a variety of ores and other grindable materials and can meet the needs of most medium-scale production lines.

Some models of 900x3000 ball mills adopt a rolling bearing design. Compared with traditional sliding bearings, this design can reduce the starting resistance torque and the friction loss of normal operation, thereby saving energy consumption.

Have Any Questions!