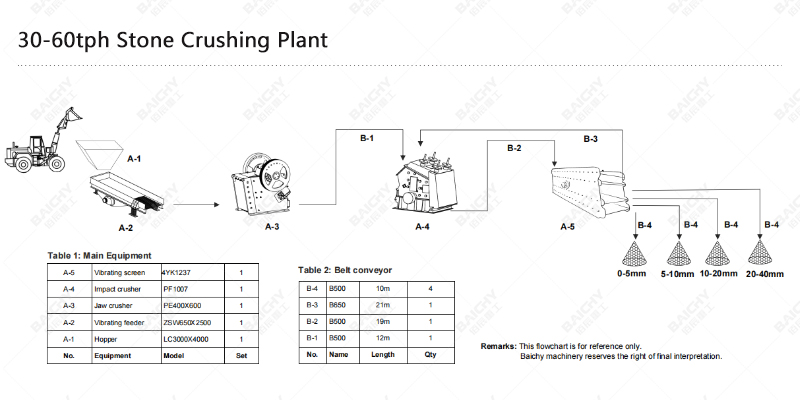

The stone-crushing production line usually includes feeding, coarse crushing, medium crushing (optional), fine crushing (optional), screening, and conveying. According to the production capacity requirements (30-60T/H), different models and quantities of equipment can be flexibly configured.

Main equipment configuration

1. Vibrating feeder: used to feed the raw materials into the coarse crushing equipment evenly and continuously to ensure the stable operation of the production line.

2. Jaw crusher: As the coarse crushing equipment in the production line, the jaw crusher has the characteristics of simple structure, reliable operation, and easy maintenance, and is suitable for ores and rocks of various hardness.

3. Cone crusher or impact crusher: According to the hardness of the raw materials and the needs of the production line, a cone crusher or impact crusher can be selected for medium crushing. A cone crusher is suitable for hard ore, while an impact crusher is more suitable for soft and medium hard ore.

4. Impact crusher: If you need to produce finer stones, you can configure an impact crusher for fine crushing.

5. Vibrating screen: used to screen the crushed stones according to the particle size to obtain products of different specifications.

6. Belt conveyor: used to transport stones at each crushing stage to ensure the continuous operation of the production line.

Production line configuration example

1. Raw material warehouse: used to store raw materials to ensure continuous feeding of the production line.

2. Vibrating feeder: feeds raw materials evenly into the jaw crusher.

3. Jaw crusher: performs coarse crushing to crush the raw materials to a certain particle size.

4. Belt conveyor: transports the coarsely crushed stones to the medium crushing equipment (such as cone crusher or impact crusher, selected according to needs).

5. Middle crushing equipment: performs medium crushing to further crush the stones.

6. Vibrating screen: screens the crushed stones to obtain products of different specifications.

(Optional) Fine crushing equipment: if finer stones are required, an impact crusher can be configured for fine crushing.

(Optional) Other auxiliary equipment: such as dust removal equipment, sand washing machine, etc., can be configured according to actual needs.

The configuration of the 30-60T/H gravel crushing production line should be flexibly adjusted according to actual needs to ensure stable operation and efficient output of the production line.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.