In iron ore beneficiation, the grinding process is one of the important processes in iron ore processing. As a commonly used grinding equipment, the ball mill plays a key role in iron ore beneficiation. Baichy Machinery focuses on displaying 3 types of ball mills and their applications in iron ore processing, aiming to help optimize the iron ore beneficiation process and improve ore utilization and production efficiency.

Working principle of ball mill

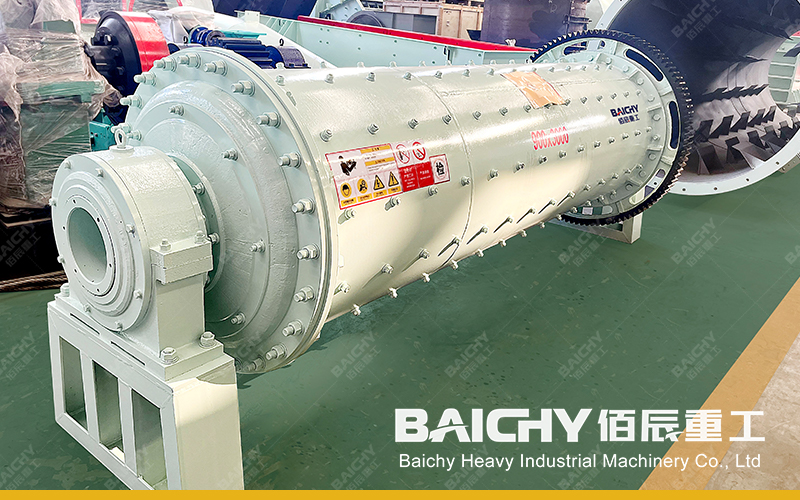

The ball mill is equipped with steel balls in a rotating cylinder, and the ore rotates with the steel balls to achieve the crushing, grinding, and mixing of the ore. The steel balls collide, rub, and wear with the ore during the rotation process, thereby crushing the ore into the required particle size. In the grinding process, the working effect of the ball mill will be affected by many factors such as the size and type of steel balls, the filling rate of the grinding media, and the rotation speed. Therefore, in actual production, the beneficiation plant should select the appropriate grinding media according to the characteristics of the ore itself, and adjust the media filling rate and the cylinder speed.

Three common iron ore beneficiation ball mills

1. Overflow ball mill

The overflow ball mill is a non-forced discharge ball mill, which mainly discharges ore through the natural inclination and overflow of the slurry surface. It is suitable for fine grinding or the second stage of two-stage grinding. The particle size of the grinding product is generally less than 0.2mm.

2. Grate ball mill

The grate ball mill is a key equipment for crushing materials after they are crushed. It crushes materials by using the falling impact and self-grinding of steel balls and ore itself in the cylinder. The grate ball mill is equipped with a discharge grid at the discharge end, relying on the grate plate to force discharge, the slurry surface is low, which can effectively prevent the ore from being over-grinded and prevent the steel balls from being discharged.

3. Dry ball mill

The dry ball mill is a ball mill equipment for processing dry materials. The dry ball mill is a horizontal cylindrical rotating device with an outer gear transmission. The material is fed into the first chamber of the mill evenly through the feeding device and the hollow shaft spiral. The chamber has a stepped lining or a corrugated lining, which contains steel balls of different specifications. The centrifugal force generated by the rotation of the cylinder brings the steel balls to a certain height and then falls, which produces a heavy impact and grinding effect on the material. After the material reaches coarse grinding in the first chamber, it enters the second chamber through a single-layer partition plate. The chamber is inlaid with a flat lining plate and contains steel balls to further grind the material. The powder is discharged through the discharge grate plate to complete the grinding operation.

Application of ball mill in iron ore beneficiation process

A ball mill is a device used for grinding and crushing ore. It grinds the ore using grinding media such as steel balls or ceramic balls through friction and impact in the rotating cylinder. In the iron ore beneficiation process, the ball mill is mainly used to grind the iron ore to a particle size suitable for the subsequent beneficiation process.

Application process of ball mill in iron ore beneficiation process

1. Crushing and screening stage: Iron ore is first crushed and screened to remove large impurities and ore particles that do not meet the requirements.

2. Grinding stage: The iron ore after preliminary treatment enters the ball mill for further grinding. The steel balls in the ball mill continuously hit and grind the iron ore during the rotation process, so that its particle size gradually decreases to meet the requirements of the subsequent beneficiation process.

3. Subsequent beneficiation process: The ground iron ore enters magnetic separation, flotation, or other beneficiation processes to separate iron concentrate and other impurities by physical or chemical methods.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.