Cone crushers are widely used in metallurgy, mining, cement, the chemical industry, ceramics, highway construction, water conservancy projects, gravel, sand making, etc. It is suitable for crushing ores and rocks with medium and above medium hardness.

The cone crusher has the characteristics of a large crushing ratio, high efficiency, low energy consumption, and uniform particle size. It is usually used for secondary, tertiary, and quaternary material reduction.

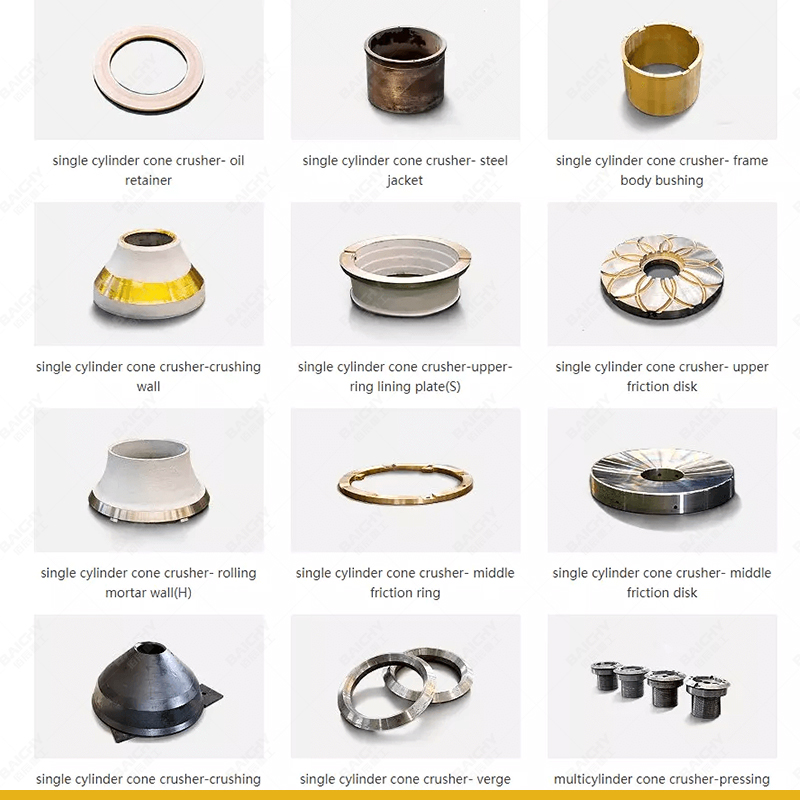

The common wearing parts of cone crusher mainly include bowl liners (concaves), mantles, feed cones, main frame liners and seat liners, protection cones, arm guards, lock nuts, distribution plates, etc.,

1. Main spare parts/replacement parts of cone crusher

• Crushing wall and rolling mortar wall

Description: A crushing wall, also known as moving cone, is fixed on the cone body with a cone head; rolling mortar wall, also known as fixed cone, works together with the crushing wall in the cone crusher to crush the material.

Replacement cycle: The service life of the crushing wall is relatively long, while the service life of the rolling mortar wall is relatively short, usually 5-6 months. The specific replacement cycle also depends on the material handling conditions, working time and intensity, and daily care and maintenance.

• Replacement method:

Before replacing the crushing wall, the equipment needs to be preheated and lubricated, and then the zinc alloy is installed and poured. After solidification, the excess zinc alloy is cleaned and other parts are installed.

The rolling mortar wall can be replaced on site. It is necessary to unscrew the adjustment screw sleeve, remove the upper chamber hopper assembly, lift the adjustment screw sleeve, remove the support plate bolts, and then remove the rolling mortar wall for replacement. When assembling, the outer surface must be cleaned and buttered.

• Spindle and cone bushing

Description: The spindle is the core component of the cone crusher, and the cone bushing works with the spindle.

Replacement cycle: Determined by wear conditions, usually consider replacement when there are obvious wear marks about 400mm below the top of the cone bushing.

Replacement method: Professional technology and tools are required for disassembly and installation to ensure installation accuracy and matching clearance.

• Thrust plate and gear

Description: The thrust plate is used to support the main shaft and bear axial force, while the gear is used to transmit power.

Replacement cycle: Depends on the wear and damage.

Replacement method: It is necessary to disassemble the relevant parts, replace the new thrust plate and gear, and ensure the installation accuracy and fit clearance.

• Frame and spherical bearing

Description: The frame is the supporting structure of the cone crusher, and the spherical bearing is used to support the moving cone and allow it to rotate.

Replacement cycle: The frame is usually strong and is not replaced frequently; the spherical bearing depends on the wear.

Replacement method: The frame replacement requires overall disassembly and installation; the spherical bearing replacement requires the removal of relevant parts and the installation of new bearings.

• Eccentric sleeve and straight bushing

Description: The eccentric sleeve and straight bushing are key components in the cone crusher, used to transmit power and bear load.

Replacement cycle: Depends on the wear.

Replacement method: It is necessary to disassemble the relevant parts and install new eccentric sleeves and straight bushings to ensure installation accuracy and fit clearance.

• Bushing and cone sleeve

Description: Bushing is used to protect the main shaft and reduce wear; the cone sleeve works with the eccentric shaft.

Replacement cycle: Depends on the wear condition.

Replacement method: When replacing the bushing, the cutting ring needs to be separated and removed by rotating counterclockwise; when replacing the cone sleeve, zinc alloy needs to be injected to prevent rotation and ensure a tight fit.

2. Other spare parts/replacement parts of cone crusher

• Conveyor belt and drive belt: used to transport materials and transmit power, and need to be checked and replaced regularly.

• Lubrication system components: such as oil seals, oil pumps oil pipelines, etc., need to be kept in good condition to ensure the normal operation of the equipment.

• Motor and electrical components: such as cables, electronic control systems, etc., need to be checked regularly to ensure the normal operation of the electrical system.

3. Importance of replacing spare parts/replacement parts of cone crusher

Timely replacement of spare parts/replacement parts of cone crusher is of great significance to maintain the normal operation of equipment, improve production efficiency, and reduce maintenance costs. By regularly checking and replacing wwornparts, potential problems can be discovered and dealt with in time to avoid losses caused by equipment downtime due to failure. At the same time, the correct spare parts selection and replacement method can also ensure that the performance and life of the equipment are fully utilized.

When selecting and replacing cone crusher spare parts/replacement parts, it is recommended to select according to the equipment model, usage and manufacturer's recommendations. At the same time, it should be ensured that the quality and performance of the spare parts meet the requirements, and follow the correct replacement methods and steps. If you are not sure how to operate or select spare parts, please consult professional technicians or manufacturers for help and guidance.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.