As we all know, when you need to crush aggregates, and mine, or recycle them, you need to choose a suitable machine from jaw crusher, cone crusher, and impact crusher. So, which one should you choose? Let's discuss it now.

First of all, the jaw crusher is the primary crushing equipment, while the cone crusher and impact crusher are the secondary crushing equipment.

What is primary crushing and what is secondary crushing? Primary crushing is the first crushing process of ore, and it is also the coarse crushing link of ore. Secondary crushing is the second crushing process of ore crushing, which is the fine crushing link of ore. It is the second process of stone crushing in the sand and gravel production line, and the stone material is produced after crushing.

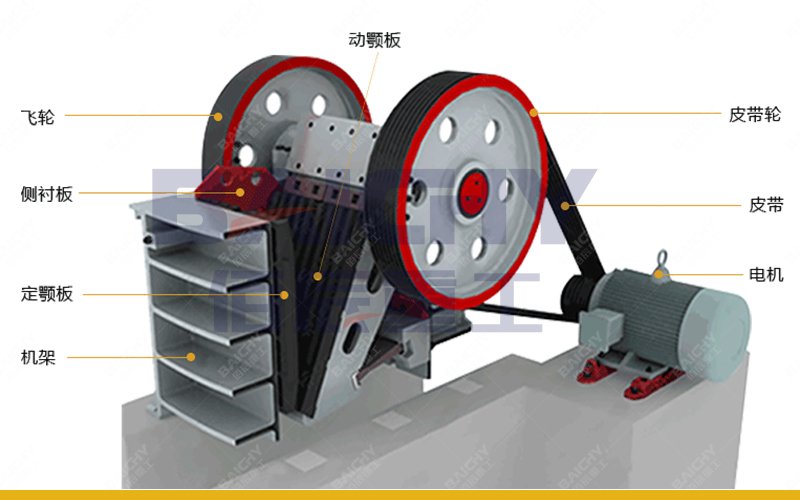

Working Principle of Jaw Crusher

During operation, the motor drives the eccentric shaft to rotate through the pulley, causing the movable jaw to periodically approach and leave the fixed jaw, thereby exerting multiple forces such as squeezing, rubbing, and grinding on the materials. The crushed materials gradually fall down until they are discharged from the discharge port.

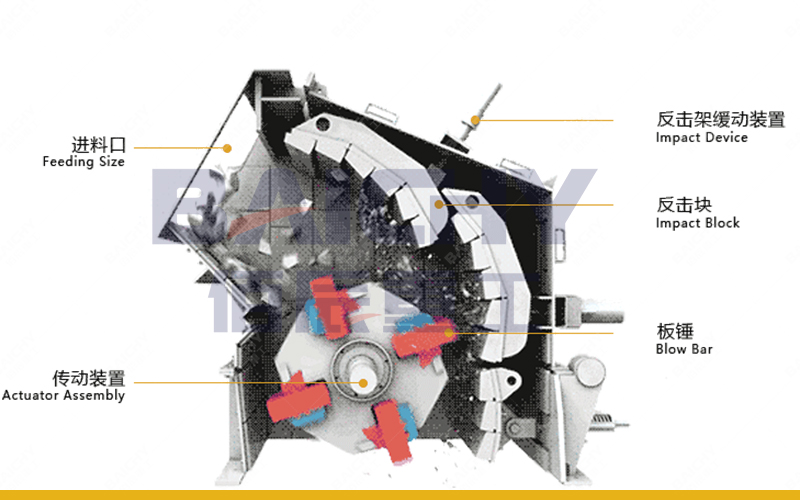

Working principle of impact crusher

Stone enters the crushing chamber from the feed port, meets the high-speed rotating rotor, and is then hit by the high-speed rotating rotor to the impact liner, and then rebounded by the impact liner back to the rotor impact area, and the above actions are repeated many times until it is crushed into stones and discharged from the bottom. The whole process adopts the "impact" crushing principle. The stone is crushed by direct collision with the machine parts, the crushing effect is more direct, and the crushing efficiency is relatively high.

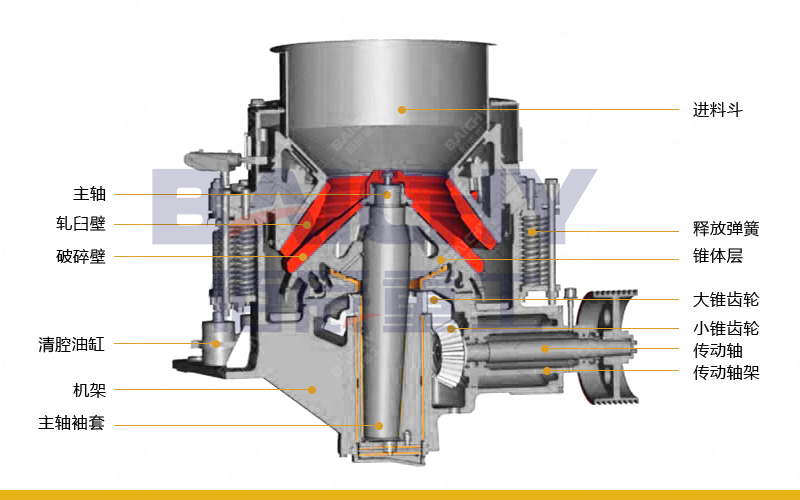

Working principle of cone crusher

When the cone crusher is working, the eccentric sleeve starts to rotate, and the moving cone rotates and swings under the force of the eccentric sleeve. The moving cone sometimes approaches the static cone (crushing) and sometimes moves away from the static cone (discharging). The material falls into the crushing chamber from the top feed port and is continuously squeezed and crushed between the moving cone and the static cone until the material particle size can smoothly pass through the minimum gap set between the moving cone and the static cone, and falls down by its own gravity and is discharged from the bottom of the cone. The whole process crushes the stone by "squeezing", and basically large stones can be completely crushed into small stones 1-2 times, with stronger crushing capacity and higher output.

What is aggregate?

Sand and gravel aggregate is a general term for materials such as sand, pebble (gravel), crushed stone, block stone, and stone in water conservancy projects. Aggregates with a particle size greater than 5mm are called coarse aggregates, which we often call gravel, and aggregates with a particle size less than 5mm are called fine aggregates, also known as sand.

What is mining?

Mining refers to stones containing some valuable minerals taken from mines. After being crushed, ground, and processed step by step, the ore can be used in engineering fields such as metal mining, metallurgical industry, chemical industry, construction industry, railway (highway) construction units, cement industry, and sand and gravel industry.

What is recycling?

Recycling is the process of producing aggregates in a profitable and environmentally friendly way and reusing valuable materials that might otherwise be considered waste.

Through understanding the crushing equipment and crushing materials, we concluded that the specific crusher to be selected depends on what size you want to crush the material into.

For Aggregate, Mining, And Recycling, if you want to crush larger materials, a jaw crusher is the best choice. If you want to crush smaller materials, an impact crusher and cone crusher or their combination with a jaw crusher are the best choices of most customers in the past.