What is Stationary Crushing and Screening Equipment?

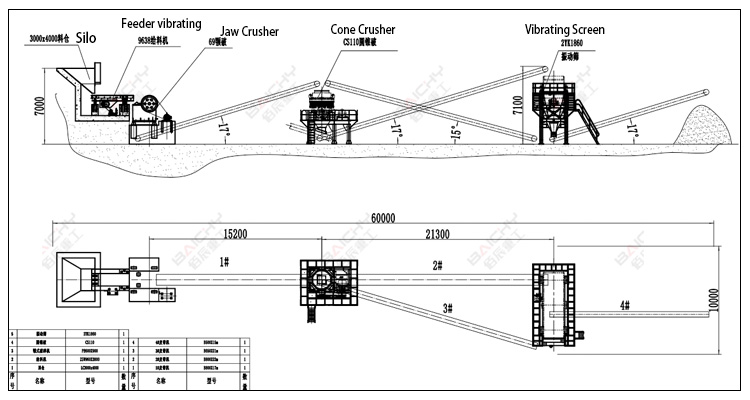

100-130TPH stationary crushing and screening equipment consists of a feeder, jaw crusher, secondary Cone crusher, vibrating screen, vibrating silo, conveyor belt, and control cabinet. Baichy100TPH fixed crushing screen can make all the equipment run smoothly. Through the combination of different models, it can be combined into a powerful crushing and screening operation line to complete multi-demand processing operations.

Baichy has professional engineering designers and more than 20 years of experience in manufacturing materials. We can provide you with a complete production design plan for free.

The Widely Uses and Advantages of Fixed Stone Crushing Line

The fixed crushing station is a large-scale mine-crushing production system integrating material receiving, conveying, crushing, screening, and fast loading. It is suitable for gravel plants with relatively fixed production areas and large crushing sites. The fixed crushing station has the advantages of diversified particle size, compact structure, stable operation, low cost, short production, installation and commissioning cycle, high mobility, and convenient and quick civil and steel construction.

Baichy fixed crushing station production line case

A mining gravel field in the Philippines found our company. They need to crush the raw material granite (250mm to 500mm) into 1-5mm and 5-10mm sizes of 10-20mm. Due to the heavy workload, they need to crush 100t/h of granite.

According to the customer's information, we have customized the solution of the granite crushing production line for the customer, including the ZSW380×3000 vibrating feeder, PE500×750 jaw crusher, PYB900 cone crusher, 3YK1860 vibrating screen.

We have added cone crushers and sand-making machines to the secondary and tertiary crushing equipment to optimize the product particles and finally obtain high-quality finished products. The production line has been well received by customers.