Ball mill structure - Baichy Machinery

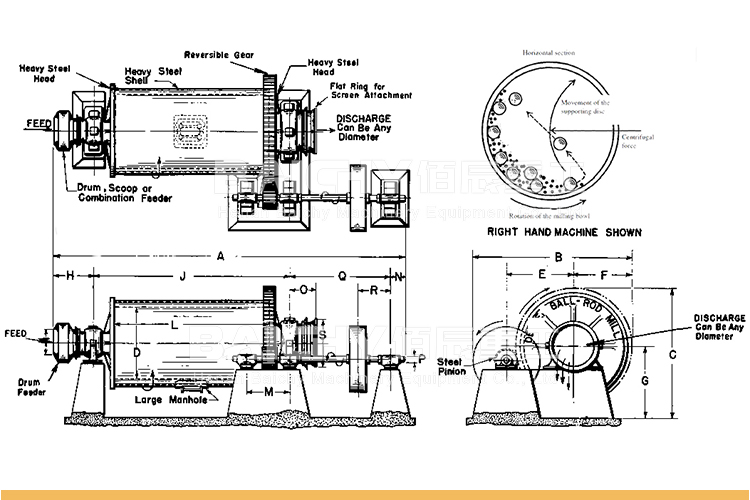

1. Cylinder: This is the main part of the ball mill. It is usually a cylindrical cylinder with grinding media such as steel balls or steel rods inside for grinding materials. There are end caps at both ends of the cylinder, and there is a hole in the middle of the end cap, called a hollow journal, which is used to support the cylinder and connect the transmission device.

2. Transmission device: mainly composed of motor, reducer, coupling, bearing, and other parts. The motor provides power, and after being decelerated by the reducer, the power is transmitted to the cylinder through the coupling, causing the cylinder to rotate at a specific speed. Bearings are used to support the cylinder and bear the load generated by it.

3. Feeding device: It usually consists of a feeding pipe, a feeding spiral, and a feeding splint, and is used to feed materials evenly into the cylinder.

4. Discharging device: It mainly consists of a discharging pipe, a discharging splint, and a discharging spiral. It is used to control the discharging speed and direction of the material to ensure that the material can flow out of the cylinder evenly.

5. Grinding media: This is a key part of the ball mill used to grind materials. It usually includes steel balls, porcelain balls, glass beads, etc. The appropriate grinding media is selected according to the properties and particle size requirements of the materials.

6. Other parts: In addition to the above main parts, the ball mill also includes some auxiliary parts, such as oil stations, control systems, etc., to ensure the normal operation and safety of the equipment.

During the working process of the ball mill, the motor drives the cylinder to rotate through the transmission device. The materials and grinding media collide, squeeze, and grind in the cylinder, thereby grinding the materials. At the same time, the inlet and outlet of materials are controlled through the feeding device and the discharging device to achieve continuous or intermittent grinding operations.