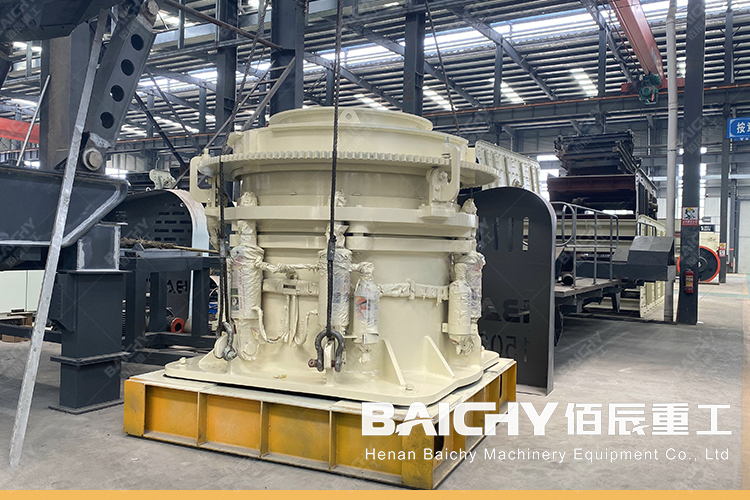

HPC multi-cylinder hydraulic cone crusher is a high-performance crushing equipment. Its characteristics and working principle make it widely used in mining, construction, metallurgy and other industries. The following is a detailed introduction to HPC multi-cylinder hydraulic cone crusher:

1. Structure and composition of HPC multi-cylinder hydraulic cone crusher

• Main components: hydraulic system, chassis, hoisting equipment, stone crushing chamber, guide plate, adjustment sleeve, etc.

• Hydraulic system: composed of oil tank, pump station, hydraulic cylinder and other components, providing the power required for the crusher to work.

• Chassis: As the supporting structure of the entire crusher, it is fixed on the ground and provides a stable working platform.

• Hoisting equipment: used to adjust the size of the stone crushing chamber to adapt to different sizes of crushed materials.

• Stone crushing chamber: core component, where materials are crushed.

• Guide plate: fixed on the stone crushing chamber, guides the flow of crushed materials, and controls the flow direction and speed of materials in the stone crushing chamber.

• Adjustment sleeve: adjusted by hoisting equipment to control the size and particle size of the stone crushing chamber.

2. Working Principle of HPC Multi-cylinder Hydraulic Cone Crusher

• Power supply: Power is provided by the hydraulic system, and the inlet and outlet of the hydraulic oil are controlled to realize the operation of the cone crusher.

• Crushing process: The crushed material enters the crushing chamber through the feed port and is crushed under the action of the conical crushing wall and guide plate.

• Particle size control: By adjusting the hoisting equipment and the adjustment sleeve, the size and particle size of the crushing chamber are controlled to meet different needs.

3. Technical parameters of HPC multi-cylinder hydraulic cone crusher

Different HPC models have different technical parameters, including moving cone diameter, cavity type, feed port size, discharge port size, production capacity, motor power and main machine weight. For example, the moving cone diameter of the HPC-160 model is 950mm, the production capacity is between 120-240t/h, and the motor power is 160kw.

4. Application fields of HPC multi-cylinder hydraulic cone crusher

Applicable to mining, building materials, metallurgy and other industries, it can perform medium and fine crushing operations on medium and above hardness materials such as iron ore, copper ore, granite, basalt, pebbles, marble, limestone, etc.

5. Product features of HPC multi-cylinder hydraulic cone crusher

• Large crushing ratio and high production efficiency.

• Less consumption of wearing parts and low operating cost.

• Laminated crushing and excellent finished product particle shape.

• Hydraulic protection and hydraulic cavity cleaning, high degree of automation, reduced downtime.

• Thin oil lubrication, reliable and advanced, and increased service life.

A variety of crushing chamber types, flexible application and strong adaptability.

Easy maintenance and easy operation.

6. Installation and precautions

• The cone crusher should be installed on a stable reinforced concrete foundation.

• During use, the equipment should be inspected and maintained regularly to ensure the normal operation of the equipment and extend its service life.

In short, HPC multi-cylinder hydraulic cone crusher is an efficient and reliable crushing equipment. Its excellent performance and wide range of applications make it an ideal choice for mining, construction, metallurgy and other industries.