Manganese ore is produced all over the world, and its main foreign production areas include India, North America, Russia, South Africa, Australia, Gabon, etc.

Manganese ore can usually be decomposed by acid, and commonly used acids include hydrochloric acid, nitric acid-hydrogen peroxide, hydrofluoric acid-sulfuric acid, phosphoric acid-nitric acid, etc. Ore samples that are not decomposed by acid can be melted and decomposed with alkaline flux or acidic flux. In addition, manganese ore generally contains impurities such as silicon dioxide, phosphorus, lead, sulfur, aluminum, arsenic, barium, calcium, magnesium, potassium and sodium. Among them, silicon dioxide, sulfur, phosphorus and arsenic are harmful impurities, especially the phosphorus content is very important, which is an important indicator for evaluating manganese ore.

The current process of processing manganese oxide ore mainly includes three processes: crushing, grinding and beneficiation. Generally, the ore is crushed to 6-0mm or 10-0mm, and then grouped. The coarse grade is eliminated and the fine grade is sent to the shaking table for selection.

The commonly used crushing equipment is the

jaw crusher. The crushed manganese ore is ground into the finished product of the required specifications in various fields by the vertical pendulum mill, and then the appropriate beneficiation process is used for beneficiation.

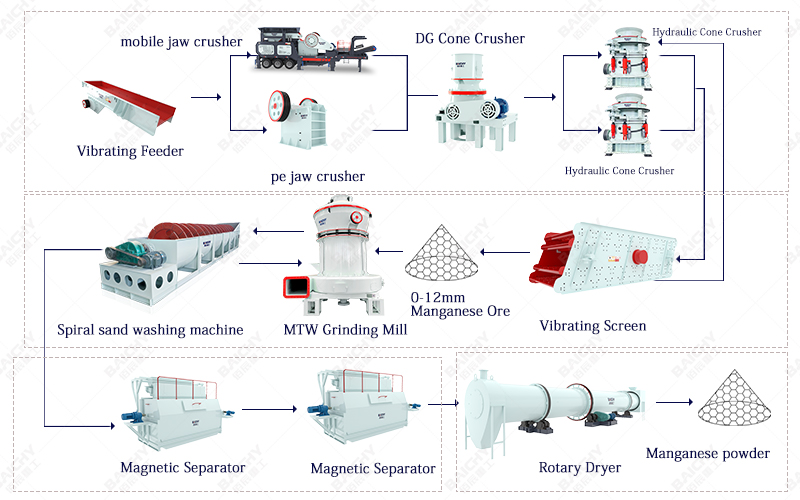

The first stage: crushing and screening - three-stage closed-circuit crushing

The large manganese ore is evenly fed into the jaw crusher or the mobile crushing station for coarse crushing by the vibrating feeder through the silo; the coarsely crushed manganese ore is screened by the vibrating screen and sent to the single-cylinder hydraulic cone crusher by the belt conveyor for medium crushing; the manganese ore material after medium crushing is sent to the multi-cylinder hydraulic cone crusher for fine crushing;

The second stage: grinding

The 0-12 mm manganese powder screened by the vibrating screen is evenly fed into the grinding machine for grinding, and screened by the spiral classifier. The powder that does not meet the requirements is sent to the grinding machine for further grinding;

The third stage: ore dressing

The manganese powder that meets the ore dressing requirements is sent to the magnetic separator for strong magnetic separation to remove impurities, and the obtained manganese powder is sent to the dryer for drying to obtain manganese concentrate.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.