Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

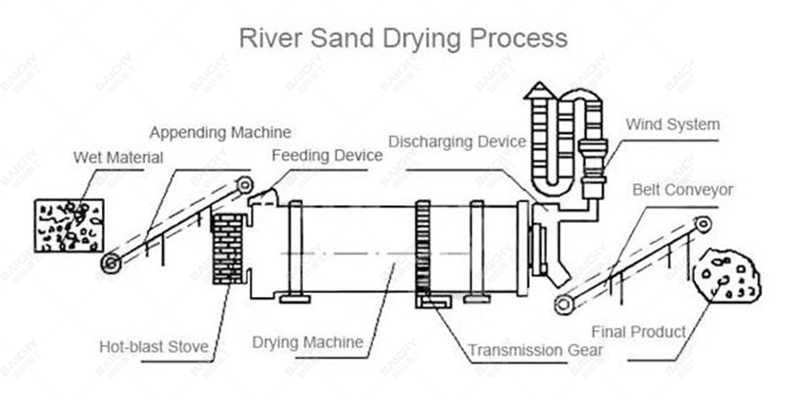

A river sand dryer is a mechanical device specially used to dry wet river sand. It uses hot air or other heat sources to heat the wet river sand to evaporate the water in the river sand, thereby achieving the purpose of drying. A river sand dryer is usually composed of a feeding device, a drying drum, a heat source system, a discharging device, a dust removal device, etc., and realizes automated and continuous drying operations through the cooperation of mechanical transmission and control systems.

The working principle of a river sand dryer is to feed the wet river sand into the drying drum through the feeding device. During the rotation of the drying drum, the river sand is fully contracted, and heat is exchanged with the hot air, so that the water in the river sand gradually evaporates. At the same time, the stirring device in the drying drum can continuously turn the river sand to make it evenly heated and improve the drying efficiency. After drying, the moisture content of the river sand is significantly reduced, and it is discharged from the discharging device after meeting the use requirements.

River Sand Dryer

River Sand Dryer

River Sand Dryer

River Sand Dryer

| Common materials | Particle size | Drying temperature |

|---|---|---|

| River sand | 4–20 mm | 80–180°C |

| Quartz sand | 0.6–4 mm | 60–80°C |

| Limestone | 16–32 mm | 150–400°C |

| Aggregate | 4–32 mm | 250–750°C |

| Bauxite | 4–8 mm | 250–850°C |

| Clay | 0.2–1 mm | 50–150°C |

• Heating device: including hot air furnace, burner, etc., mainly used to send hot air into the drying drum, heat the river sand, and evaporate its moisture.

• Cooling device: including fan, cooler, etc., mainly used to collect heat in the drying drum, reduce the temperature of the river sand, and make it reach the ideal drying condition.

• Transport device: including rotating mechanism, agitator, etc., mainly used to push the river sand into the drying drum evenly for uniform drying.

• Discharging device: mainly used to discharge the dried river sand from the dryer.

River sand dryer has many advantages, such as high drying efficiency, large processing capacity, high degree of automation, and easy operation. It is widely used in many industries such as building materials, metallurgy, chemical industry, glass manufacturing, etc., and is one of the indispensable important equipment in these industries. Through the treatment of river sand dryers, the utilization rate of river sand can be greatly improved, production costs can be reduced, and product quality can be improved. At the same time, it also helps to reduce environmental pollution and achieve sustainable development.

Have Any Questions!