Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

Slag is a by-product of the blast furnace ironmaking process. Specifically, when iron ore is reduced to metallic iron through iron oxide at high temperatures, impurities such as silica and alumina react chemically with lime to form silicates and aluminosilicates. A melt of the main ingredients. After quenching, these molten materials will form loose, porous granular materials. This is what we call blast furnace slag, or slag for short.

Slag is widely used in industrial production. Through processing and refining, slag can be made into slag cement, slag powder, slag Portland cement, slag wool, etc., which not only saves energy consumption but also contributes to environmental protection.

The Slag Vertical Roller Mill is based on the slag raw material to build the production process. For example, slag raw materials can be applied to cement manufacturing plants. The processed slag material can be filled in cement to process slag cement, which can improve the performance of cement, reduce cost, and increase the benefit of the whole cement plant.

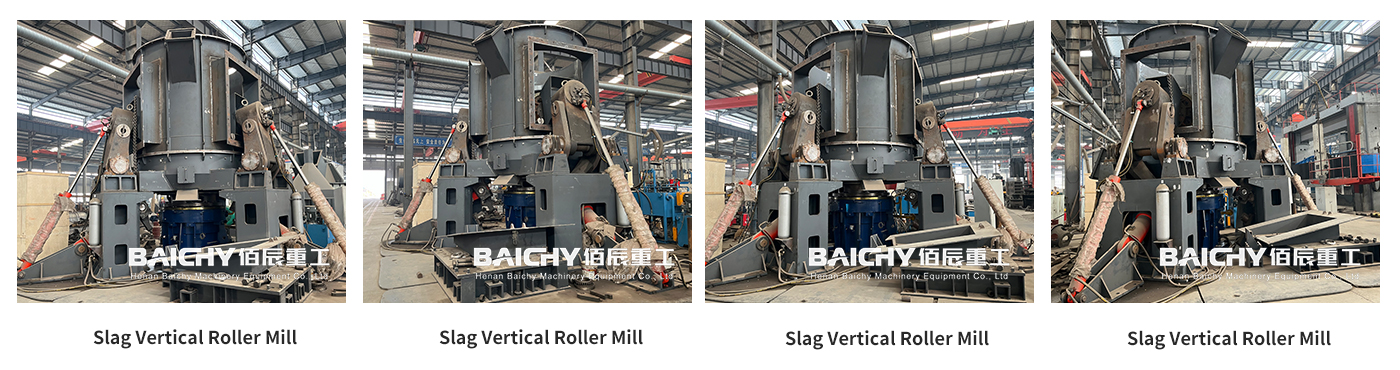

Slag vertical roller mill, referred to as a vertical mill, is a piece of equipment specially used for slag grinding and processing. It integrates fine crushing, grinding, drying, powder selection, and transportation, providing a continuity and stability guarantee for slag grinding production and significantly improving slag grinding efficiency.

In slag grinding production, the slag vertical roller mill plays a central role. Through its efficient and stable grinding process, it not only improves the output and quality of slag grinding but also provides high-quality admixtures for the production of concrete and other products, thus improving the performance of concrete.

The complete set of equipment is mainly composed of jaw crusher, bucket elevator, cement silo, vibrating feeder, slag mill, fan, powder collector, bag filter, etc.

The slag needs to be crushed into small sizes. Commonly used crushing equipment includes jaw crushers, impact crushers, cone crushers, and slag mobile crushing plants.

At present, it has become the mainstream trend in the building materials industry to replace the amount of cement in concrete and cement products with slag micro powder. One of the main equipment in the slag powder production line is the slag mill.

There are so many types of cement mills that can be selected for slag grinding plants.

| Model | Grinding table dia.(mm) | Max feeding size(mm) | Discharge size(um) | Discharge size(mesh) | Air-in tempreture(℃) | Air-out tempreture(℃) | Input material moisture | Final moisture | Capacity(t/h) | Motor Power(kw) |

|---|---|---|---|---|---|---|---|---|---|---|

| SRM1300 | 1300 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 10-35 | 185-250 |

| SRM1500 | 1500 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 13-48 | 250-355 |

| SRM1700 | 1300 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 18-68 | 355-600 |

| SRM1900 | 1900 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 23-85 | 450-600 |

| SRM2200 | 2200 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 36-135 | 710-1000 |

Have Any Questions!