Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

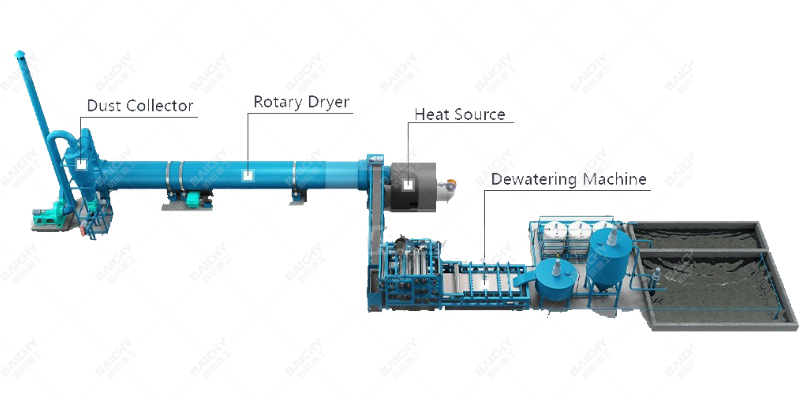

Sludge dryers play an important role in sewage treatment plants and are mainly used to treat the residual sludge generated during sewage treatment. These sludges usually contain a lot of water and are bulky, making them difficult to handle and dispose of directly. Through the treatment of sludge dryers, the moisture content of sludge can be significantly reduced, and its volume and weight can be reduced, making it easier to transport, store, and use it later.

In the chemical industry, sludge dryers are often used to treat various sludges generated during chemical production. These sludges may contain toxic and harmful substances, and direct discharge will cause serious pollution to the environment. Through the treatment of sludge dryers, the water in the sludge can be evaporated, the volume and toxicity of the sludge can be reduced, and the difficulty and cost of subsequent treatment can be reduced.

Sludge Dryer

Sludge Dryer

Sludge Dryer

Sludge Dryer

| Spec. (Dia.x Length mm) |

Volume(m³) | Capacity (t/h) | Gradient(%) | Highest Inlet Air Temperature(℃) |

Rotate Speed(r/min) | Main Motor(kw) |

|---|---|---|---|---|---|---|

| Φ600x6000 | 1.7 | 0.5-1.5 | 3~5 | 700~800 | 3~8 | 3 |

| Φ800x8000 | 4.1 | 0.8-2.0 | 3~5 | 700~800 | 3~8 | 4 |

| Φ800x10000 | 5.1 | 0.8-2.5 | 3~5 | 700~800 | 3~8 | 4 |

| Φ1000x10000 | 7.9 | 1.0-3.0 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1000x12000 | 9.4 | 1.2-3.2 | 3~5 | 700~800 | 3~8 | 11 |

| Φ1200x8000 | 9 | 1.9-2.4 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1200x10000 | 11.3 | 2.2-3.0 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1200x12000 | 13.6 | 2.4-3.2 | 3~5 | 700~800 | 3~8 | 7.5 |

| Φ1500x12000 | 21.2 | 4.5-5.7 | 3~5 | 700~800 | 2~6 | 15 |

| Φ1500x14000 | 24.7 | 5.3-6.6 | 3~5 | 700~800 | 2~6 | 15 |

| Φ1500x16000 | 26.5 | 5.7-7.1 | 3~5 | 700~800 | 2~6 | 15 |

| Φ1800x12000 | 30.5 | 6.5-8.1 | 3~5 | 700~800 | 2~6 | 18.5 |

| Φ1800x14000 | 35.6 | 7.6-9.5 | 3~5 | 700~800 | 2~6 | 18.5 |

| Φ1800x16000 | 40.7 | 7.8-10.2 | 3~5 | 700~800 | 2~6 | 18.5 |

| Φ2000x18000 | 56.5 | 8.4-12.3 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2000x20000 | 62.8 | 9.0-13.6 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2200x16000 | 60.8 | 11.4-15.8 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2200x18000 | 68.3 | 12.8-16.2 | 3~5 | 700~800 | 1.5~6 | 22 |

| Φ2200x20000 | 75.9 | 13.0-16.5 | 3~5 | 700~800 | 1.5~6 | 30 |

| Φ2400x16000 | 72.3 | 13.5-16.9 | 3~5 | 700~800 | 1.5~5 | 37 |

| Φ2400x18000 | 81.4 | 17.4-21.7 | 3~5 | 700~800 | 1.5~5 | 45 |

| Φ2400x20000 | 90.4 | 19.3-24.1 | 3~5 | 700~800 | 1.5~5 | 55 |

| Φ2600x24000 | 127.4 | 27.2-34.0 | 3~5 | 700~800 | 1.5~5 | 75 |

| Φ2600x28000 | 148.6 | 28.6-36.2 | 3~5 | 700~800 | 1.5~5 | 75 |

| Φ3000x20000 | 141.3 | 30.1-37.7 | 3~5 | 700~800 | 1.5~5 | 85 |

| Φ3000x25000 | 176.6 | 37.7-47.1 | 3~5 | 700~800 | 1.5~5 | 90 |

| Φ3200x25000 | 201 | 42.9-53.6 | 3~5 | 700~800 | 1.5~5 | 110 |

1. High efficiency and energy saving: The sludge dryer adopts advanced drying technology and a heat recovery system, which can significantly improve the utilization rate of thermal energy and reduce energy consumption. At the same time, by optimizing the design and manufacturing process, the operating cost and maintenance cost of the equipment can be further reduced.

2. Green and environmental protection: During the drying process, the sludge dryer adopts multi-stage purification and dust removal equipment, which can effectively remove the dust and harmful gases generated during the drying process and meet the national environmental protection standards. In addition, by reasonably controlling the drying temperature and time, the risk of secondary pollution during the sludge drying process can also be reduced.

3. Easy operation: The sludge dryer adopts an automatic control system, which can realize remote monitoring and intelligent adjustment of the equipment. The operator only needs to monitor and operate the equipment through the control panel or remote terminal, which greatly improves work efficiency and safety.

4. Wide range of applications: The sludge dryer is suitable for various types of sludge treatment, including sludge generated by urban sewage treatment plants, sludge generated by industrial wastewater treatment, and agricultural waste. By adjusting the process parameters and structural form of the dryer, it can adapt to the characteristics and treatment requirements of different sludges.

Sludge dryer has broad application prospects in the fields of urban sludge treatment, industrial wastewater treatment, and agricultural waste resource utilization. With the continuous strengthening of environmental protection policies and the improvement of people's awareness of resource recycling, sludge dryers as efficient and environmentally friendly sludge treatment equipment will be more widely used and promoted.

At the same time, with the continuous advancement of technology and the continuous development of the market, sludge dryers will also be continuously upgraded to meet higher requirements for sludge treatment.

Have Any Questions!