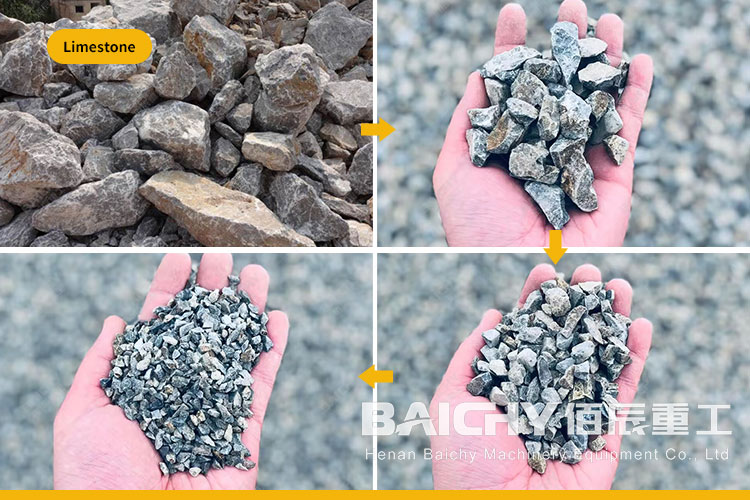

The 200t/h (200 tons per hour) limestone crushing plant is a high-efficiency production line specially used for crushing limestone. Its main goal is to process large amounts of limestone raw materials and break them into particles of specific sizes to meet the needs of subsequent processing or use.

This crushing station usually includes the following main parts and processes:

● Raw material transportation: Limestone raw materials are continuously and stably transported to the feed port of the crusher through loaders or conveyor belts.

● Crusher: The crushing station is the core equipment. It usually uses a crusher with high efficiency, wear resistance, and a large crushing ratio, such as an impact crusher or cone crusher. These crushers use high-speed rotating hammers or crushing cones to break limestone raw materials into particles of the required size.

● Screening system: The crushed limestone particles are screened through the screening equipment to separate the particles that meet the requirements, while the particles that do not meet the requirements are returned to the crusher for re-crushing.

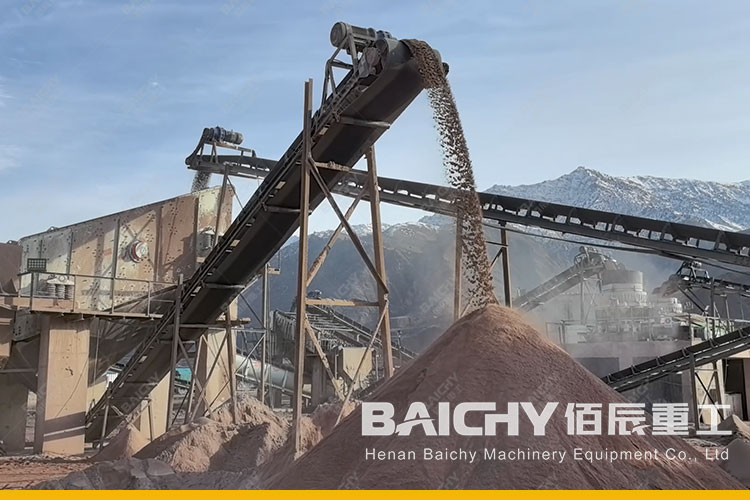

● Transportation and storage: The screened limestone particles are transported to designated storage areas through conveyor belts or other conveying equipment, waiting for subsequent use or further processing.

Dust removal and environmental protection equipment: Since a large amount of dust is generated during the crushing process, crushing stations are usually equipped with dust collectors and environmental protection equipment to ensure that the production environment is clean and meets environmental protection requirements.

Control system: The entire crushing station is centrally controlled through the electrical control system to achieve automated and intelligent production, improve production efficiency, and reduce labor costs.

A 200t/h limestone crushing station is usually a highly integrated, automated production line that can process large amounts of limestone raw materials quickly and efficiently to meet the needs of industrial production. When designing and building such a crushing station, multiple factors such as the nature of the raw materials, production needs, and environmental protection requirements need to be considered to ensure its stable, reliable, and efficient operation.

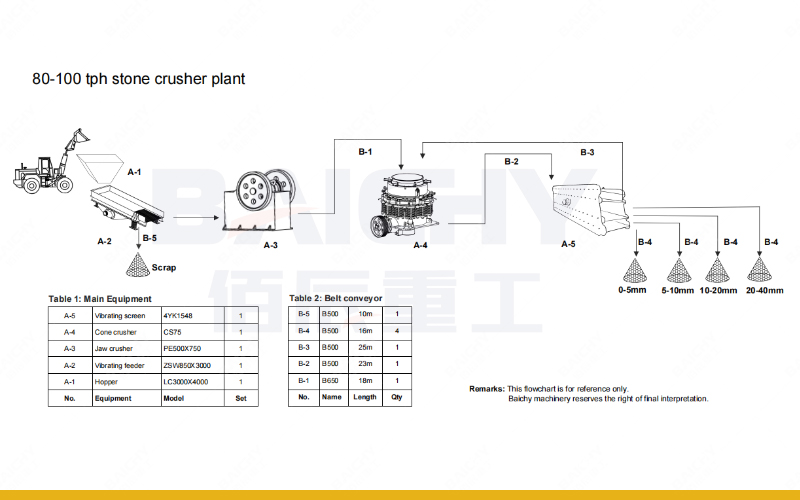

Fixed model configuration of 200t/h limestone crushing station

The fixed model configuration of a 200t/h (200 tons per hour) limestone crushing plant can be adjusted according to specific needs and site conditions, but the following is a typical configuration scheme:

1. Feeding equipment:

Use a ZSW490×110 vibrating feeder. This feeder has uniform, continuous, and quantitative feeding characteristics, which can ensure the efficient operation of the crusher.

2. Crushing equipment:

Primary crushing: You can choose the PE-750×1060 jaw crusher as the primary crushing equipment. This crusher is suitable for processing larger limestone and has the characteristics of a large crushing ratio and uniform product particle size.

Secondary crushing: According to the particle size requirements of the finished product, the PF-1315 impact crusher can be selected for secondary crushing. The impact crusher can handle medium-hard materials and has the characteristics of high crushing efficiency and good particle size control.

3. Screening equipment:

Use the 2YK2460 vibrating screen for screening, and configure different screens according to the required particle size of the finished product to ensure that the crushed limestone particles meet the specified particle size requirements.

4. Conveying equipment:

Several conveyors are configured to transport crushed limestone particles from the crusher to the screening equipment and to transport the screened finished particles to designated storage areas.

5. Dust removal and environmental protection equipment:

Configure dust collectors and corresponding environmental protection equipment, such as bag dust collectors or wet dust collectors, to control the dust generated during the crushing process and ensure that the production environment is clean and meets environmental protection requirements.

6. Control System:

The electrical control system is used to centrally control the entire crushing station to achieve automated and intelligent production. The control system can monitor the operating status of the equipment, adjust crushing parameters, record production data, etc., to improve production efficiency and reduce labor costs.

It should be noted that the above configuration scheme is only a typical example, and the actual configuration may be adjusted based on factors such as the hardness and granularity requirements of the limestone, site conditions, and investment budget. Therefore, when designing and constructing a 200t/h limestone crushing station, it is recommended to conduct detailed consultation and cooperation with a professional crushing equipment manufacturer or engineering company to ensure the rationality and feasibility of the configuration plan.