The stone crushing plant plays a vital role in the mining industry. Its main task is to crush, screen and process the mined natural stone to meet the stone particle size and quality requirements of different industries. The following is the main workflow of the stone crushing plant:

1. Raw material preparation: First, the stone crushing plant needs to receive the natural stone extracted from the mine. These stones may include rocks, ores, etc. of various hardnesses. When receiving raw materials, preliminary quality inspection and classification are required to ensure that the raw materials meet the requirements for crushing and processing.

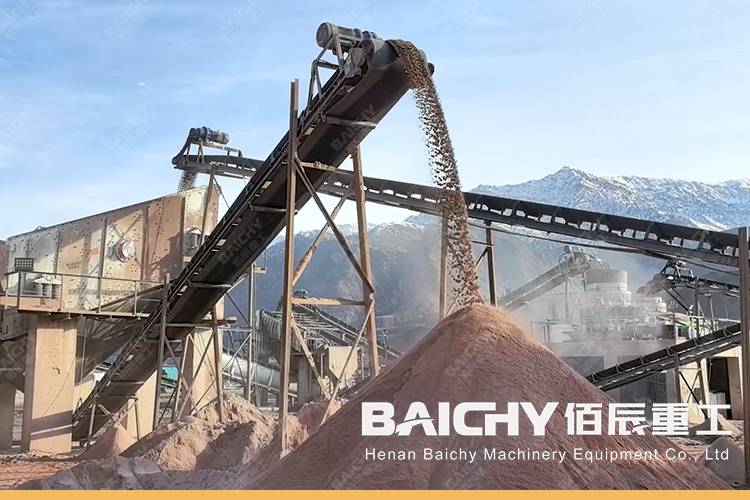

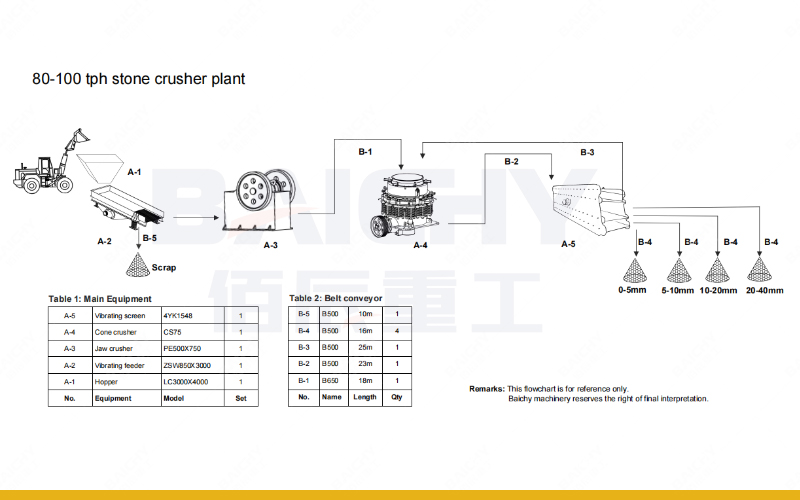

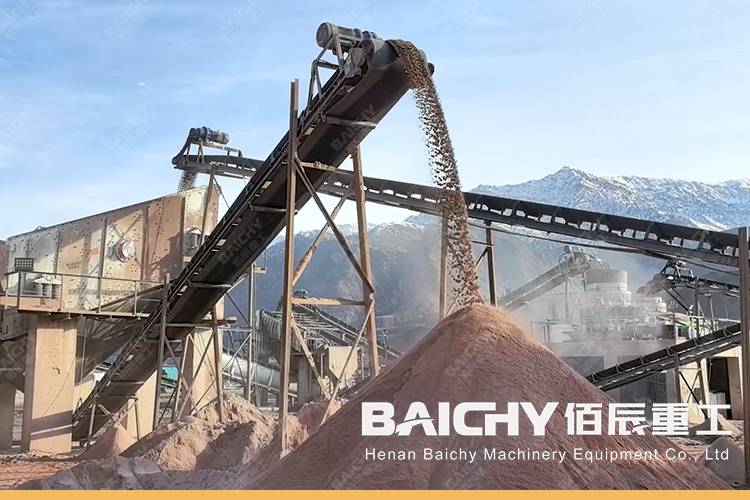

2. Crushing process: Crushing is the core link of a stone crushing plant. According to the hardness and particle size of the raw materials, select the appropriate crushing equipment for crushing. Common crushing equipment includes jaw crushers, cone crushers, impact crushers, etc. These equipment break raw materials into the required particle size through different working principles (such as extrusion, impact, shearing, etc.). During the crushing process, regular maintenance and upkeep of the crusher is also required to ensure its normal operation and extend its service life.

3. Screening process: The crushed stone needs to be screened to remove particles that do not meet the requirements. Screening equipment usually includes vibrating screens, trommel screens, etc. This equipment can screen the stone according to the set particle size requirements, and send the stones that meet the requirements to the next process, while the stones that do not meet the requirements are returned to the crusher for re-crushing.

4. Processing process: According to customer needs, the stone crushing plant can also further process the stone, such as sand making, sand washing, etc. Sand-making equipment can break stones into smaller particle sizes to meet the demand for sand in construction, road and other industries. Sand washing equipment can clean and remove impurities from the sand to improve its quality and purity.

5. Finished product storage and transportation: The finished stone products after crushing, screening and processing need to be stored and transported. Finished products are usually stored in silos or yards for ready supply to customers. During the transportation process, it is necessary to choose the appropriate transportation means and routes to ensure that the finished products can be delivered to customers safely and quickly.

6. Environmental protection measures: The stone-crushing plant will produce certain noise, dust, wastewater, and other pollutants during the production process. In order to protect the environment, stone-crushing plants need to take a series of environmental protection measures, such as installing dust removal equipment, noise control equipment, wastewater treatment equipment, etc., to reduce environmental pollution and damage.

The stone-crushing plant processes natural stone into finished stone products that meet the requirements through crushing, screening, processing, and other technological processes, providing high-quality raw materials for construction, roads, water conservancy, and other industries. At the same time, stone-crushing plants also need to pay attention to environmental protection and production safety to ensure the sustainable development of the production process.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.