A complete calcium bromide grinding production line usually involves multiple links from raw material preparation, chemical reaction synthesis, crystallization, drying, grinding, screening, and packaging to finished product delivery.

1. Raw material preparation

• Main raw materials: usually include calcium hydroxide (Ca(OH)₂) and liquid bromine (Br₂) or other bromine-containing compounds.

• Raw material inspection: ensure that the purity and quality of the raw materials meet production requirements.

2. Chemical reaction synthesis

• Reaction process: react calcium hydroxide solution with liquid bromine under appropriate conditions to generate calcium bromide (CaBr₂) and water (H₂O). This step is usually carried out in a reaction tank, and parameters such as reaction temperature, stirring speed, and reaction time need to be controlled.

• Reaction product: after the reaction, a solution containing calcium bromide is obtained.

3. Crystallization

• Precipitation separation: calcium bromide is precipitated from the solution by adding appropriate precipitants or adjusting solution conditions.

• Crystallization process: in the crystallizer, calcium bromide gradually crystallizes to form solid particles.

4. Drying

• Purpose: Remove moisture from the crystals and improve the purity and stability of the product.

• Equipment: Common drying equipment includes ovens, drying towers, etc.

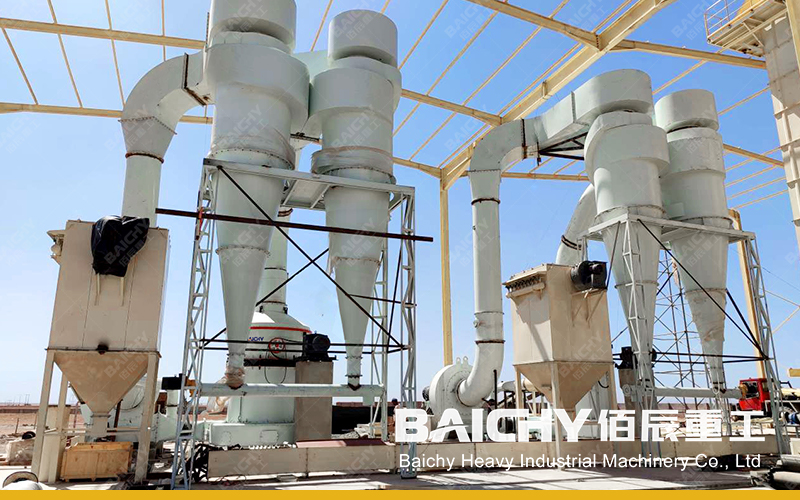

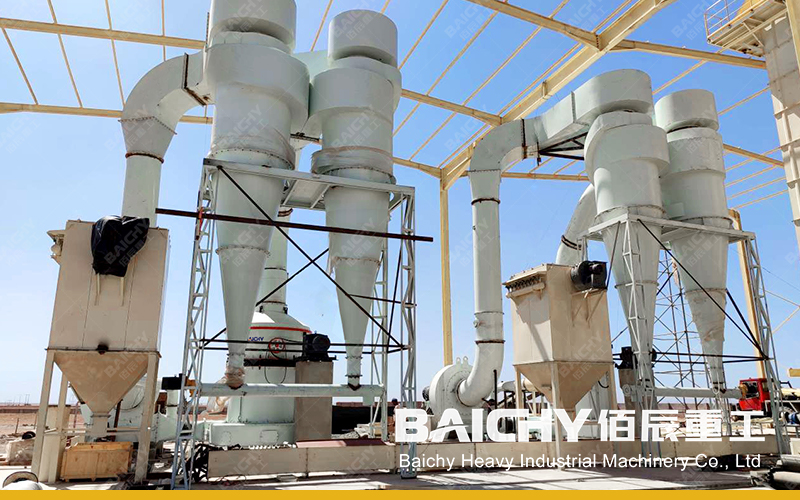

5. Grinding

• Purpose: Grind the dried calcium bromide solid particles into a powder of the required particle size.

• Equipment: Use grinding equipment such as ball mills, vibration mills, and airflow mills for operation.

6. Screening

• Purpose: Use screening equipment to classify the ground powder according to particle size to meet the needs of different customers.

• Equipment: Vibrating screens, rotary vibrating screens, etc.

7. Packaging

• Packaging materials: Select appropriate packaging materials such as plastic bags, paper bags, woven bags, etc. according to the characteristics of the product and customer needs.

• Packaging method: Automated packaging line or manual packaging to ensure the sealing and moisture resistance of the product.

8. Finished product delivery

• Quality inspection: Conduct quality inspection on the finished product to ensure that the product meets relevant standards and customer requirements.

• Storage and Transportation: Store qualified products in a dry, cool, and ventilated warehouse and distribute them according to the prescribed transportation methods.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.