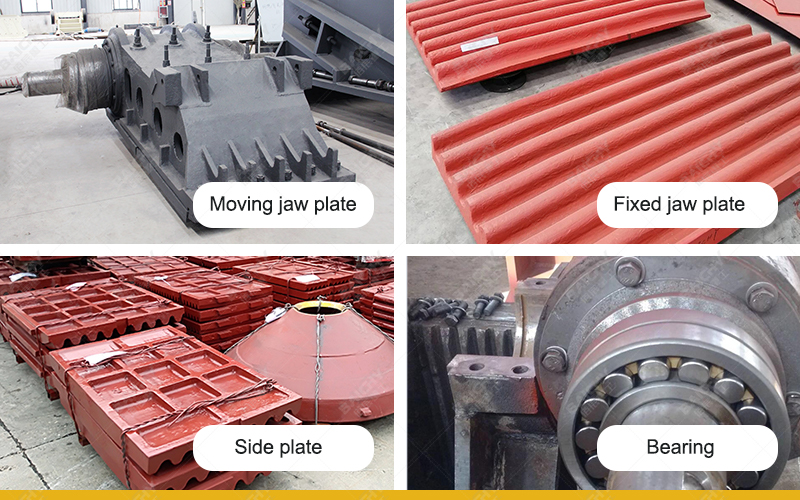

The vulnerable parts of the PE900x1200 jaw crusher mainly include movable jaw plate, fixed jaw plate, side guard plate, toggle plate, spring pull rod, and spring parts; these parts are subjected to great impact and wear during the crushing process, so they need to be regularly inspected and replaced to ensure the normal operation of the equipment.

PE900x1200 jaw crusher movable jaw plate and fixed jaw plate

• Function: The movable jaw plate and fixed jaw plate are the main working parts of the jaw crusher and directly participate in the crushing process of the material.

• Features: Under huge impact loads, the edges are prone to wear, and the wear is mostly concentrated in the middle and lower parts.

• Material: In order to extend the service life, high manganese steel and other materials with good hardness and wear resistance are generally used, such as ZGMn13 material.

• Replacement cycle: Generally from a few months to about half a year, depending on factors such as use conditions, stone hardness, and equipment load.

PE900x1200 jaw crusher side guard plate

• Function: Located on the left and right inner sides of the jaw crusher frame, used to protect the crusher body.

• Features: It will wear out under the impact of materials, and needs to be replaced when the wear reaches a certain level.

• Replacement cycle: Usually longer, generally about half a year, depending on the use conditions and the working intensity of the crusher.

PE900x1200 jaw crusher toggle plate

• Function: An important component connecting the moving and fixed jaw plates, and also a safety part of the crusher.

• Features: When uncrushable materials fall into the crusher and the machine exceeds the normal load, the toggle plate will break immediately to protect the machine from damage.

• Replacement cycle: Regular inspection and replacement are required, usually about half a year.

PE900x1200 jaw crusher spring pull rod and spring components

• Function: It mainly connects the adjustment seat and the rear support plate, adjusts the size of the discharge port, and maintains the stability of the jaw plate, while absorbing and buffering the vibration and impact during the crushing process.

• Features: It has a good buffering and vibration reduction effect, which can effectively reduce the impact damage to the machine during the crushing process.

• Replacement cycle: generally about half a year, depending on factors such as use conditions, work intensity, and maintenance.

PE900x1200 jaw crusher bearing

• Function: jaw crusher bearings mainly bear radial loads when the equipment is working.

• Features: 4 sets of spherical roller bearings are used, with good load-bearing and automatic self-aligning performance.

• Replacement cycle: generally more than one year, depending on bearing quality, use conditions, and maintenance.

Users need to regularly inspect and maintain these wearing parts, and replace severely worn parts in time to ensure the normal operation and production efficiency of the equipment. At the same time, choosing high-quality parts suppliers and wearing parts with high-quality certification is also an important measure to reduce equipment failure rate and extend equipment life.