Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

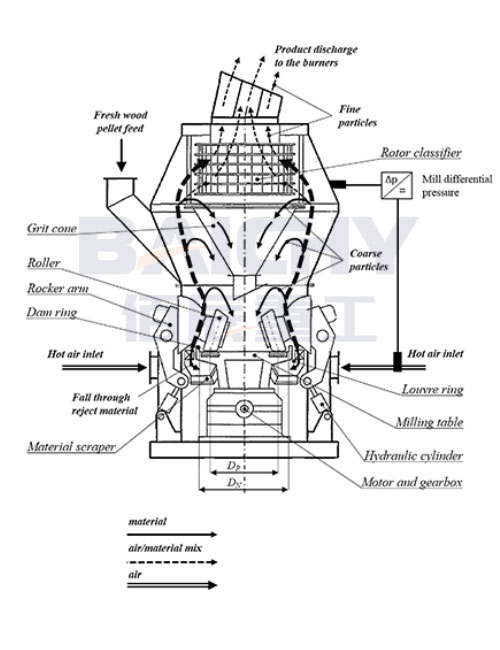

The coal vertical roller mill has less dust, low noise, high-efficiency granular composition, and excellent combustion performance due to its special design and structure Chaeng(Great wall machinery) Vertical Roller Mill has a simple process, compact structure, product fineness of 80μmR 3%, with steady and average product fineness.

Vertical Coal Mill's special design structure and production process create a higher production efficiency with lower energy consumption, less dust, and lower noise than a ball mill, which meets the national standard of the energy-saving industry. Baichy Machinery’s Vertical Coal Mill technology reaches the international advanced level, and its manufacturing quality reaches the leading domestic level, and is the preferred equipment for grinding raw coal and soft coal.

| Model | Grinding table dia.(mm) | Max feeding size(mm) | Discharge size(um) | Discharge size(mesh) | Air-in tempreture(℃) | Air-out tempreture(℃) | Input material moisture | Final moisture | Capacity(t/h) | Motor Power(kw) |

|---|---|---|---|---|---|---|---|---|---|---|

| SRM1300 | 1300 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 10-35 | 185-250 |

| SRM1500 | 1500 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 13-48 | 250-355 |

| SRM1700 | 1300 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 18-68 | 355-600 |

| SRM1900 | 1900 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 23-85 | 450-600 |

| SRM2200 | 2200 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 36-135 | 710-1000 |

Baichy Machinery has nearly 20 years of experience as a professional manufacturer, optimizing product upgrades, using the most advanced technology, and integrating crushing, drying, grinding, grading, and conveying functions into a system. The optimization and improvement of the functions of the vertical coal mill reduces the investment in related auxiliary equipment and improves systematization.

The vertical coal mill adopts direct grinding, and the grinding roller directly grinds above the grinding disc, with high grinding efficiency, low energy consumption, and guaranteed products. With the continuous development of vertical mill technology, the roller design is improved, which makes it easier to form a material layer than ordinary vertical rollers, achieving the required product fineness and increasing output. At the same time, the application of high-quality wear-resistant materials increases its stability, reduces wear, and ensures the continuous operation of the production line.

The material layer grinding principle is adopted to ensure product fineness. The SRM series vertical coal mill adopts the most advanced dynamic and static combined powder selector, with high classification efficiency and a large adjustment range. It can achieve the fineness requirement of 0.08mm, and the retention rate is below 3%, which can meet the needs of most cement production lines for inferior coal or anthracite.

Have Any Questions!