In many sand and gravel production lines, when the raw materials are crushed into sand, how can the aggregate be distinguished together? If you want to distinguish between stone and sand, choose a stone screening device to help.

1. There are many types of stone screening equipment to meet various needs.

Stone crushing and screening equipment is indispensable equipment for large-scale stone crushing, medium crushing, fine crushing, and sand making. It is divided into two types: comprehensive screening machine and fixed screening machine.

Comprehensive screening machine: mobile crusher + vibrating screen

The comprehensive screening equipment means that the crushing equipment and screening equipment are loaded on one vehicle to realize multiple transfer operations and shuttles between different stone factories. After the stone is crushed, it goes to the screening equipment, and the crushed stone is sorted by the mobile screening equipment through the screening holes of the stone, such as stones of different sizes or sand with finer particles.

Mobile screening machine

The mobile screening machine is suitable for narrow gravel sites without fixed installation, which saves the installation time and labor of accessories, and the automatic integrated production saves labor.

Stationary Screening Machine: Vibrating Screen

Vibrating screens can be divided into eccentric semi-vibrating screens, inertial vibrating screens, and resonant screens according to the movement characteristics of the working parts. The operation of sieving a mixture of different particle sizes according to particle size is called a sieving operation. According to the different roles of screening operations in gravel production, the distinction between gravel and sand can be completed.

2. What is the screening effect of stone screening equipment?

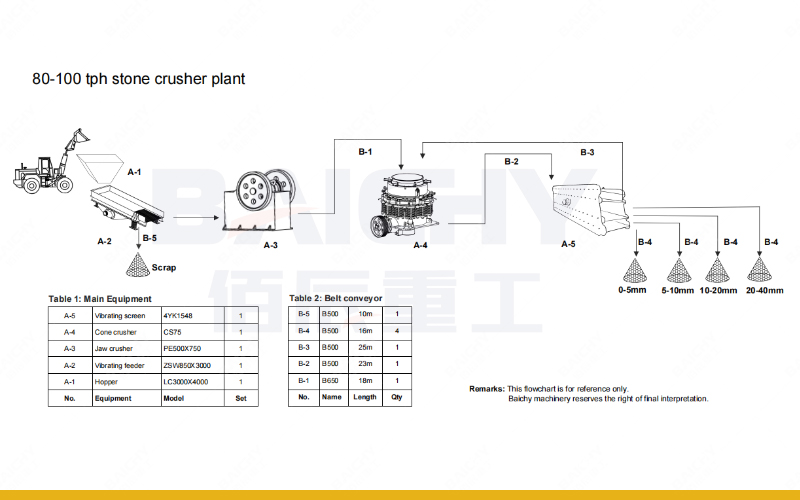

The stone sieving machine uses the vibration of the vibrating motor as the source of vibration power so that the material can move forward in a straight line while being thrown on the sieve. Through the multi-layer sieve, various sizes of sieves and sieves can be produced. The finished product can reach various specifications such as 0-5mm, 5-10mm, 10-20mm, 20-30mm, 30-40mm, etc., to meet the production needs of users.