Mine and Quarry Crushing Process

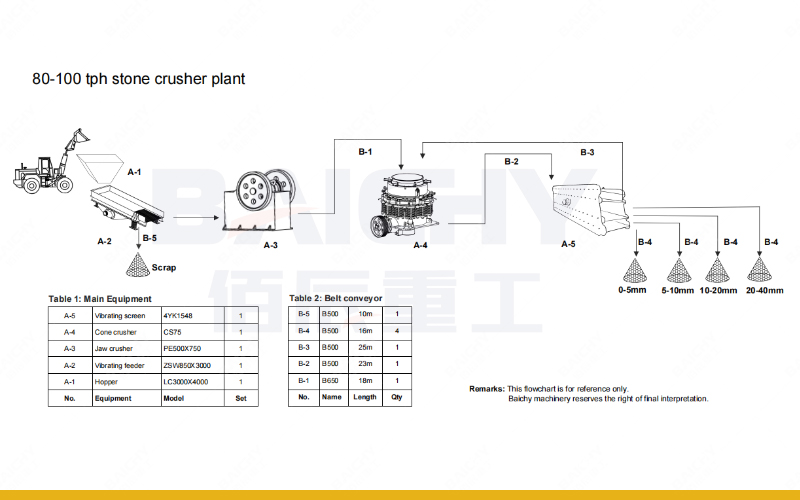

The quarry sand and gravel production line needs to have a coarse crushing stage, a medium crushing stage, and a sand-making stage, and each stage needs to be equipped with different types of crushing equipment.

Jaw crushers are generally used for primary crushing, and jaw crushers can crush both soft and relatively hard materials. The secondary crushing equipment has a variety of options, commonly used are jaw crusher, impact crusher, cone crusher, and other equipment.

Different secondary crushers are selected for different production situations, and different types of secondary crushers have their own production advantages and disadvantages. Here, the advantages and disadvantages of common secondary crushers are analyzed and introduced.

Advantages and Disadvantages of Secondary Crusher

1. Jaw Crusher

Advantages: As secondary crusher equipment, the jaw crusher is suitable for relatively hard materials and has a high crushing ratio. The obvious advantage is that the operating cost and investment cost are both low.

Disadvantages: The needle flake content in the finished product is high, so when the jaw crusher is used as a secondary crusher, it cannot be used in industries that require high sand and gravel quality.

2. Impact Crusher

Advantages: Suitable for materials with low hardness such as limestone raw materials, the finished product has uniform particle size, and the crushed particle size can be selected; the acceptable input material is relatively large, generally ≤700mm, and the one-time investment cost is low.

Disadvantages: The impact plate of the impact crusher is easily worn by the impact of stones. As a vulnerable part, the wear is more serious especially when crushing materials with higher hardness.

3. Cone Crusher

Advantages: Cone crusher is suitable for materials with high hardness, high crushing ratio, rich equipment types, single-cylinder and multi-cylinder, and spring and hydraulic. It is long, does not need to be replaced frequently, and has low operating costs.

Disadvantages: The needle-like and flaky content of the finished product is relatively high. As an aggregate, the compressive strength is not as good as that of the impact crusher, and the one-time investment cost is higher.

How to Choose the Right Crushing Equipment?

The quarry production line has different configuration schemes for different sites; when the site is sufficient, a fixed crushing production line can be used, and the crushing process is clear; if the construction site is small or limited, then a mobile crushing station can be used to operate. This type of crusher is installed on a mobile crusher, which can be moved along with the construction location, which improves the flexibility of construction operations.

Baichy is a professional mechanical equipment company, we have our own factory and engineering designers. If you have needs, you can contact us, we can provide professional design services.